Volume III ● Issue 2/2012 ● Pages 257–277

News and Views

Results of the microscopic Analyses of Vessels from Assemblages of the Modlnica Type (with Furchenstichkeramik) from Site 5 in Modlnica, Kraków District, Poland

Albert Zastawnya*, Anna Rauba-Bukowskab , Joanna Trąbskac, Barbara Trybalskad

aArchaeological Museum in Kraków, Senacka 3, 31-002 Kraków, Poland

bArcheometria, Staszica 10/7, 31-162, Kraków, Poland

cInstitute of Archaeology, University of Rzeszow, Hoffmanowej 8, 35-016 Rzeszow, Poland

dUniversity of Science and Technology in Kraków, Mickiewicza 30, 30-059 Kraków, Poland

Article info

Article history:

Received: 1 November 2011

Accepted: 23 December 2012

Key words:

Eneolithic

Lesser Poland

Furchenstichkeramik

microscopic analyses of vessels

Abstract

At site 5 in Modlnica near Kraków, the first settlement in south-eastern Poland (Małopolska) with materials of the Furchenstichkeramik type was discovered. The following article presents the results of microscopic analyses of several characteristic forms of vessels. The main objective of the research was to determine the mineralogical and petrographic composition of the ceramic fabrics, identify deliberate admixtures (raw materials), determine their origin as well as to analyse the white material encrusting the pottery decorated with the incised ornament (Furchenstichkeramik). The research indicates significant differences between the technology of production of the analysed materials and the manufacture of pottery attributed to local Neolithic cultures. The most essential one seems to be the discovery of volcanic glass in the pottery fabric suggesting that the material may derive from outside the region. These results verify the archaeological typological-stylistic assessment of findings from Modlnica as an assemblage of Danubian origin (Slovakia, Moravia). The results of the research presented below are the first microscopic analyses of assemblages with materials of the Furchenstichkeramik type.

1. Archaeological context of findings

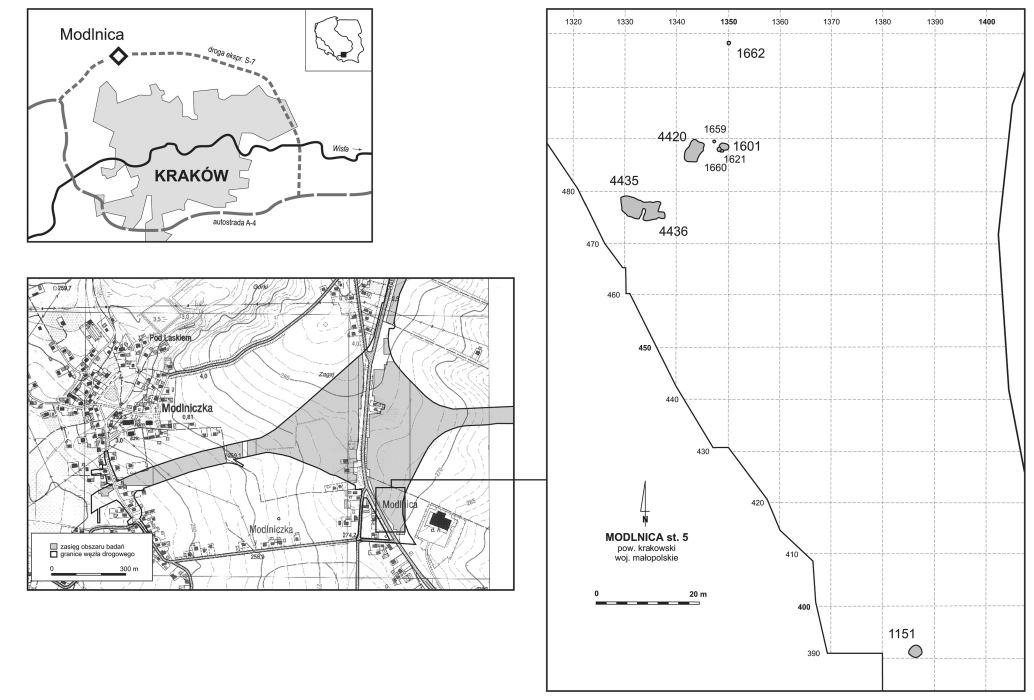

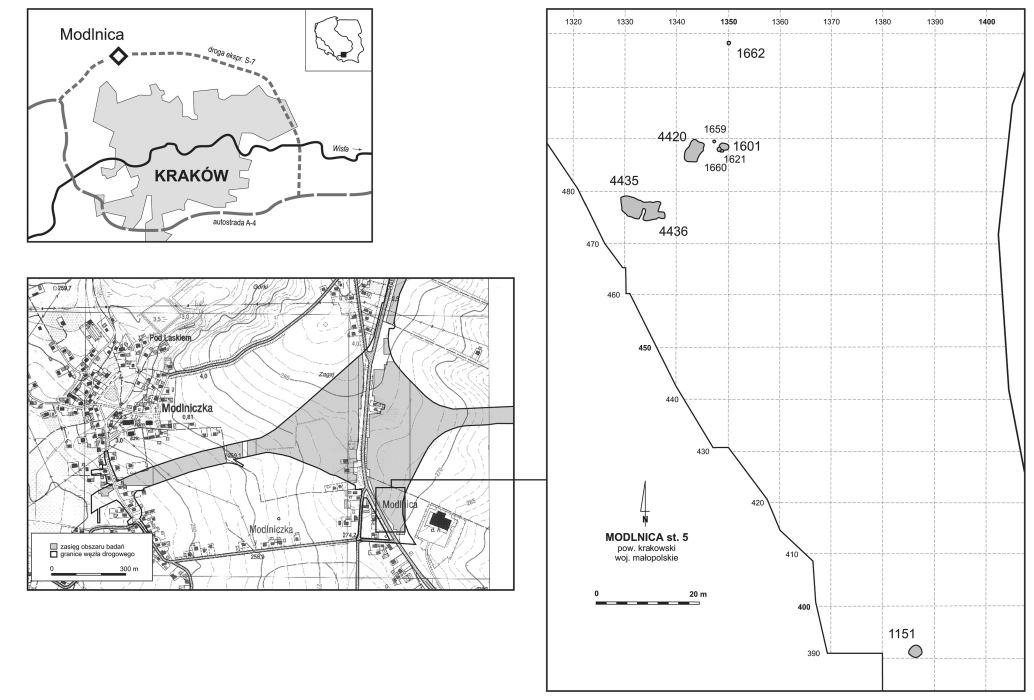

In 2008, rescue excavations (Zastawny, Grabowska in print) preceding the construction of the northern ring road of Kraków (Figure 1) unearthed the first examples of pottery decorated with the incised ornament (Furchenstichkeramik) in south-eastern Poland (Małopolska, Lesser Poland). The findings are unique due to their settlement character.

In the area of the small settlement at site 5 in Modlnica, 12 features were discovered (Figure 1). A number of them had rectangular outlines and formed a distinct concentration in the southern part of the explored area. At the site, archaeologists found more than 2,000 pottery fragments and 40 flint artefacts discovered in pits as well as in secondary deposits in modern features. The pottery decorated with the incised ornament (Furchenstichkeramik), was partly encrusted with white material, which resembles the pottery decoration of the Bajč-Retz group. The discussed assemblages also contained additional particularly characteristic elements. Among them were jugs of the Baalberge type, pots with handles of the Hunyadihálom type and high Epi-Lengyel bowls with the upper parts of the body strongly bent inward. Until now these types of findings (e.g. handles of the Hunyadihálom type) have only rarely been found in this area. In addition, a number of them were previously unknown in Neolithic/Eneolithic inventories from Lesser Poland. The taxonomic coherence of the material from Modlnica as well as the lack of any analogies to local inventories indicates their south-Carpathian origin. We can assume that these materials must have appeared near Kraków owing to migrations of communities. The closest analogies to our materials can be found in the territory of Moravia and western Slovakia. They correspond to the chronological horizon of the Funnel Beaker Culture IB – Baalberge – Bajč-Retz – Čataj – Lažňany – Hunyadihálom (see: Točik 1961; Janák 1993; Ruttkay 1999; 2004; Pavúk 2001; 2004; Kovárník 2004; 2008).

The discovery of pottery decorated with the incised ornament (Furchenstichkeramik) in a region located north-east of the Carpathian Mountains significantly enlarges the territorial extent of the findings of this type in Central Europe. The great significance of the discoveries from Modlnica entitles us to introduce these materials to specialist literature under their own name: assemblages of the Modlnica type. Apart from the archaeological, taxonomic and chronological research into pottery from assemblages of the Modlnica type, microscopic analyses of the vessels deriving from the main ceramic forms were also carried out. This article presents the results of these analyses.

2. Petrographic Examinations of the vessels

2.1 Research objectives

The research aimed at addressing the following fundamental issues: the first was to determine the mineral and petrographic composition of the ceramic fabrics and as a result to define their technology of manufacture. Since the assemblage in question most probably derives from outside Lesser Poland, the second issue was to therefore examine all the samples paying special attention to the raw material the vessels had been made from in order to determine its origin. A comparison was also made between the analysed material and the pottery attributed to the Funnel Beaker culture from site 5 in Modlnica, with any conceivable connections to the pottery of the Malice culture from the same site also having been checked (Rauba- Bukowska 2011). Finally, the results of all the analyses mentioned above were compared and analysed. This mineral and petrographic research into the pottery of the assemblage in question is the first of this kind, therefore we do not have any comparative materials as a reference point.

2.2 Material

A series of nine pottery fragments, deriving from assemblages of the Modlnica type, was subjected to analyses. The vessels represent all the characteristic forms distinguished within the materials from site 5 in Modlnica, including pottery decorated with the incised ornament (Zastawny, Grabowska, in print). The juxtaposition of samples and morphological features of the sherds has been presented in charts (Tables 1, 2). The samples were denoted with the symbol “MF” (Modlnica, Furchenstich) with consecutive ordinal numbers: 1, 2, 3…

2.3 Results

During the comparative analyses of the samples, the following elements were taken into consideration:

– the mineral and petrographic composition (expressed as the percentage share of the particular components, Table 3),

– granulometry (percentage content of the grains of various diameters, Table 4),

– texture of the ceramic mass.

2.3.1 The mineral and petrographic composition

The vessels in question were made of ceramic fabrics characterized by quite a diversified mineral and petrographic composition (Table 3). Fundamental components included clay minerals (34–78%) and quartz pelite (circa 16–46%). Clastic material is usually composed of well smoothed grains of quartz, quite often of K-feldspars and more rarely of plagioclases. The fabrics also contain muscovite (up to 9%) and opaque minerals (up to 9%) as well as volcanic glass. In certain cases (MF6, MF7), the quantity of fragments of igneous rocks is significant (up to 14%). Fragments of grog are numerous in the analysed fabrics (up to 20%). Heavy minerals are accessory components. In the samples, components such as flint, chalcedony, sedimentary rocks (limestone), metamorphic rocks (apart samples MF7) or organic material were not registered.

2.3.2 Granulometry

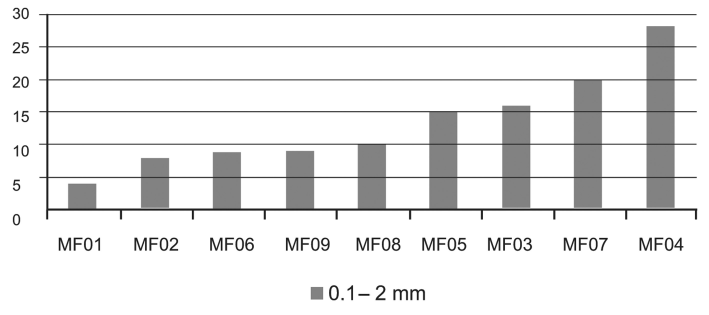

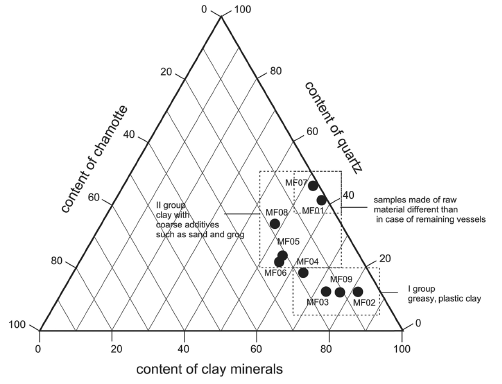

During the granulometric analysis, all the crystalline grains as well as the clay clasts were measured ranging in size from the aleurite (0.01–0.1 mm), arenite (0.1–2.00 mm) to the rudite fraction (>2 mm), on the basis of Wentworth scale (1922). The samples are characterized by a changeable quantity of fine and coarse grains (Table 4). The preparations can be divided into groups: fine-grained (to 10% of the arenite fraction) and medium-grained /10–30% of the arenite fraction (Figure 2).

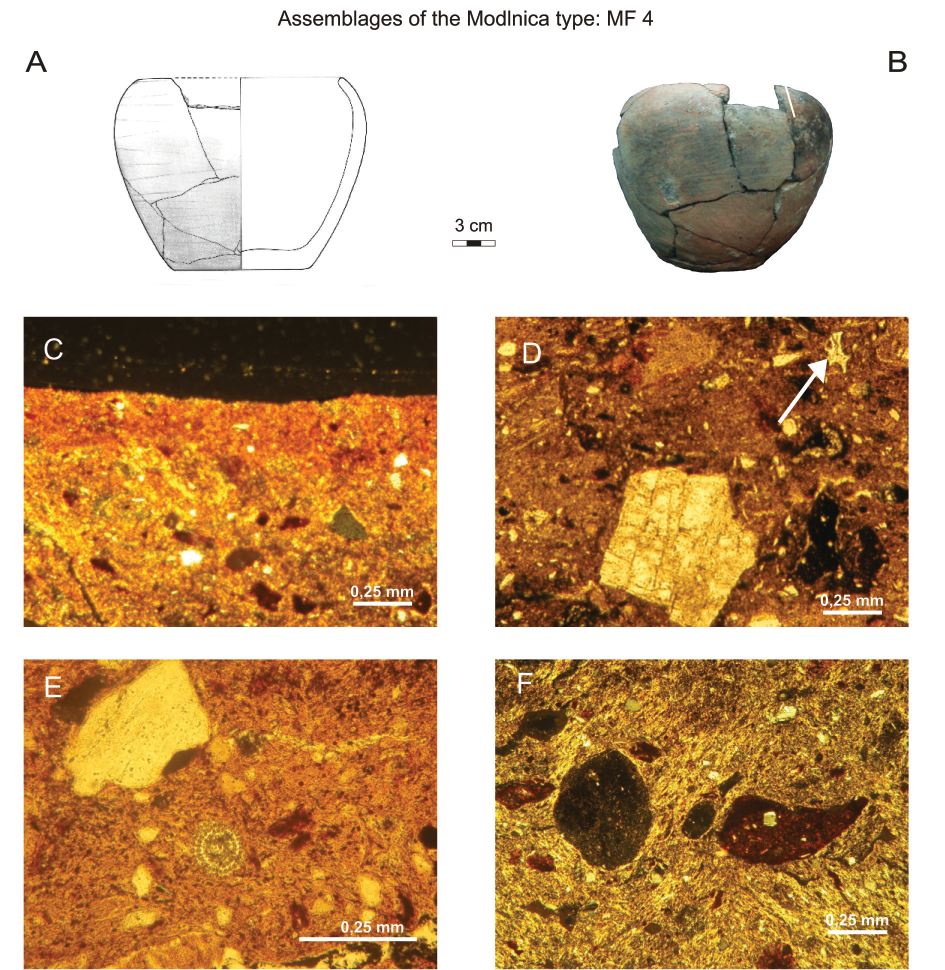

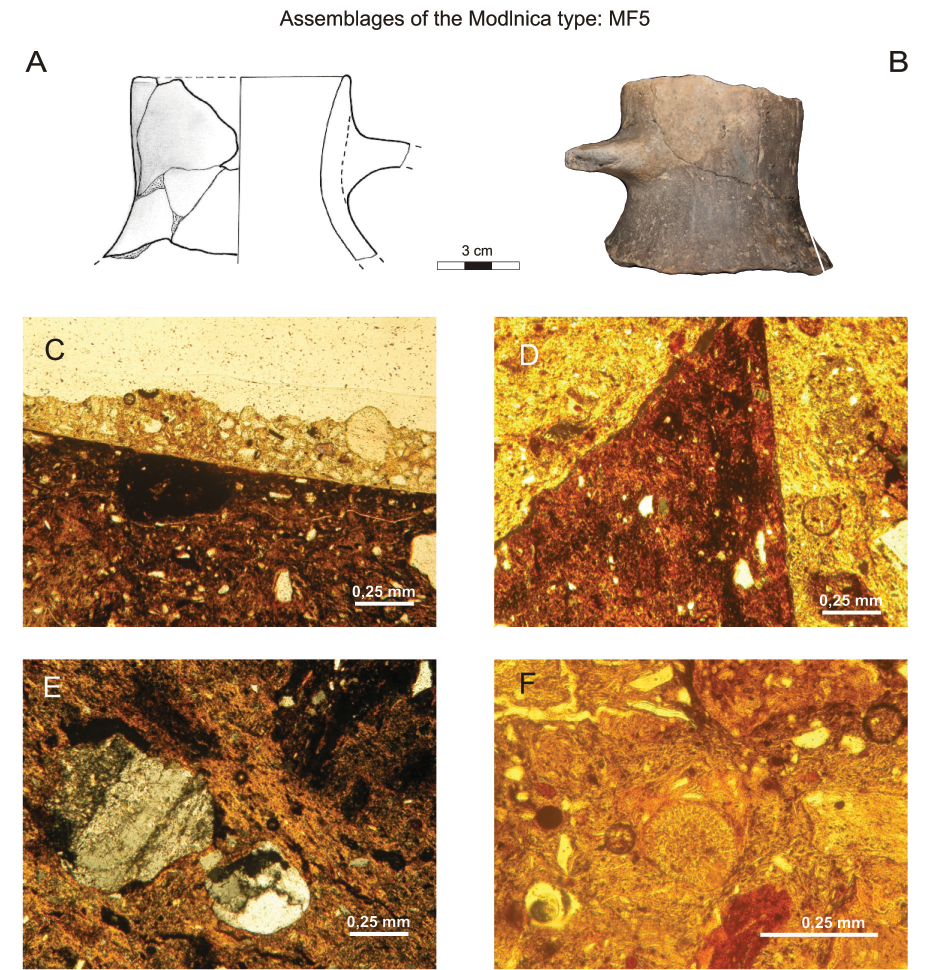

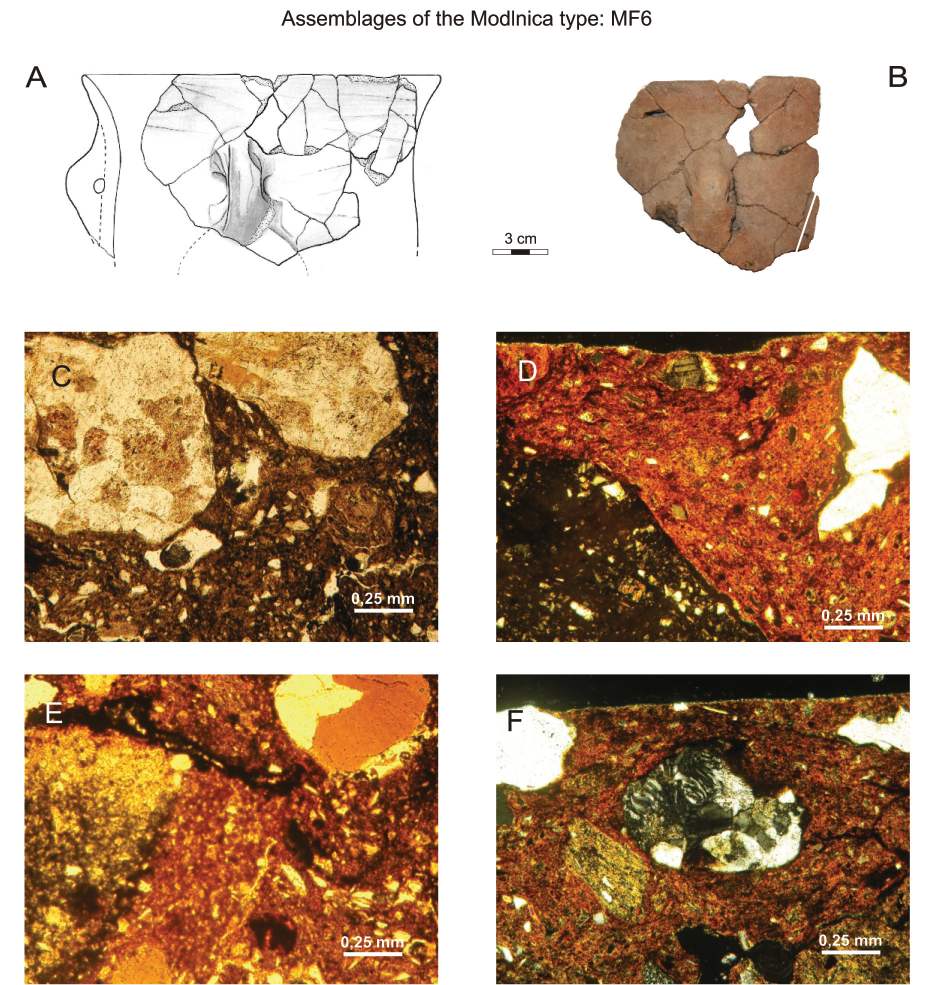

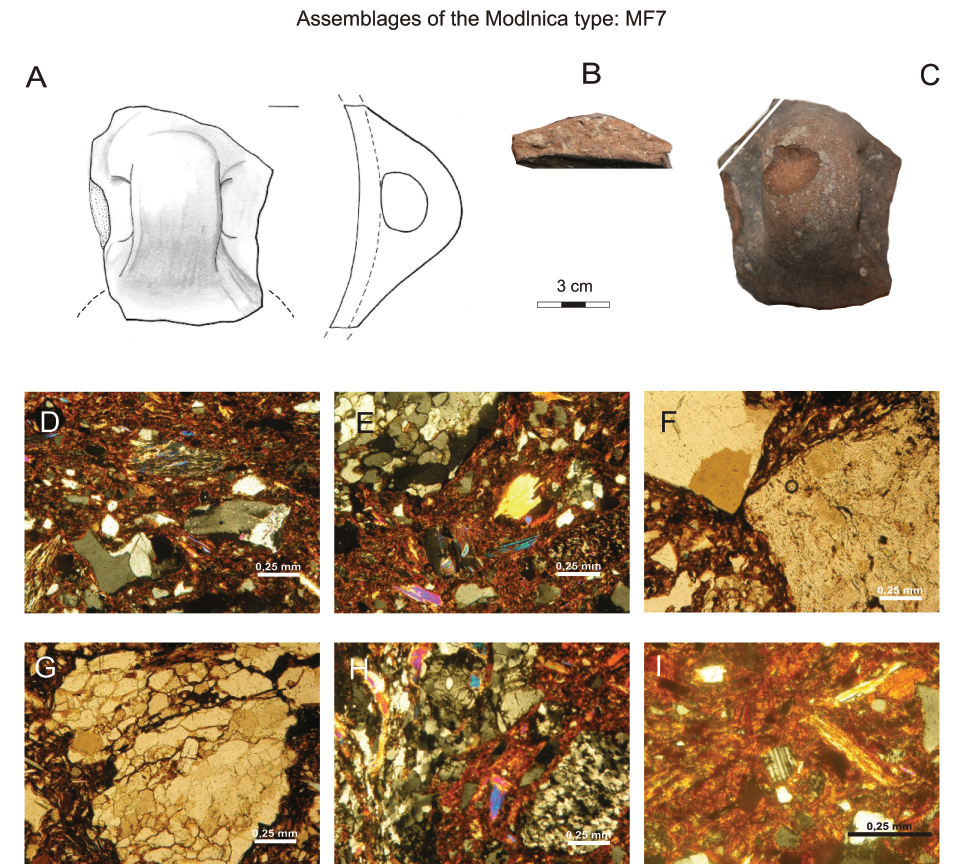

The majority of the samples were composed of fine-grained fabrics: a small bowl (MF1, Figure 3), cup (MF2, Figure 4), a pot with a handle decorated with a shield (MF6), a pot with a plastically formed band in the shape of an inverted “U” (MF8) and a jug of the Baalberge type with an elbow-shaped handle beneath the edge (MF9). The four vessels were composed of medium-grained fabrics: a pear-shaped vessel (MF3, Figure 5), a bowl (MF4, Figure 6), a jug of the Baalberge type (MF5, Figure 7) and an amphora with a handle finished with a discoid application (MF7). The presence of larger clasts of grog affects the coarseness of the samples (e.g. MF6, Figure 8). However, the sample MF7 (Figure 9) is coarse grained, because of numerous fragments of igneous rocks content.

2.4 Interpretation and discussion

2.4.1 The raw materials

Miocene clay undoubtedly constituted the basic raw material for the production of most of examined vessels (MF2, MF3, MF4, MF5, MF6, MF9). Firstly, the presence of the remains of microfauna such as radiolariae confirms this assumption (Figure 4: D; Figure 6: E; Figure 7: F). Secondly, more or less transformed shards of volcanic glass are present in the clay (Figure 4: C, D; Figure 10: D; Figure 11: E). They are typical of deposits of such kind, reflecting increased volcanic activity in Miocene in the Carpathian area. Shards of volcanic glass were registered in numerous samples (apart from sample MF7). In the MF1 very small particle of volcanic glass are present in the fragments of grog and fragments of clay clasts.

Volcanic glass, constituting the prevailing fabric of volcanic ash, had been blown from a volcanic centre e.g. Central Slovakia, Slanské Vrchy, Vihorlat, Tokay, Bükk Mountains (Hungary) and Romanian area. The volcanic ash had formed continuous deposits of tuffs and tuffites across a relatively large area. Tuffite levels are recognized in the Carpathian area. They are characterized by a thickness from several centimetres to 2–3 meters (in the Subcarpathian region), maximally, even up to several hundred meters (Transcarpathian Ukraine). In the region of Kraków, material containing volcanic glass is known from certain local outcrops in the Bochnia area (Bukowski et al. 2010).

We may assume that this raw material may derive from areas where it still occurs, in the inner-Carpathian region: in Slovakia, the Subcarpathian part of the Ukraine or northern Hungary. In these territories, intense Miocene volcanic activity has been established and material containing volcanic ash is commonly accessible (Lexa et al. 2010). It cannot be excluded that the volcanic glass registered in pottery from Modlnica could have derived from Miocene clays in the region of Kraków. The presence of volcanic glass was not, however, established in the pottery of the Malice culture, Wyciąże-Złotniki group of the Lengyel-Polgar circle and the Funnel Beaker culture from site 5 in Modlnica. Instead, grains of calcareous rocks, flints and fine grains of chalcedony were observed which demonstrates their local character (Rauba-Bukowska 2011). These kinds of raw materials were not registered in any of the analysed samples from assemblages of the Modlnica type. The content of the volcanic glass and biological marine fragments were stated in the LBK ceramic material from the site Modlnica 5. However the origin of this raw materials is not yet established (Czekaj-Zastawny, Rauba-Bukowska in print). All the arguments presented above lead to the conclusion that the raw materials containing volcanic glass without admixture of local material such e.g. flint and chalcedony, were from outside Lesser Poland, in all probability from the inner-Carpathian region. This conclusion however requires further study on the raw materials.

Three samples contain large amount of quartz pelite. They are have been made with silty clay (MF1, MF8) and with clay loam (MF7). The identification of origin of raw materials is more complicated. Sample MF1 is a fabric made of clay which is indicated by the presence of microfauna and which does not contain volcanic glass in the clay matrix. We may assume that it could have been made of local sub-Cracovian raw materials. Sample MF8 contains large amount of quartz pelite and bigger rounded grains and also relicts of marine fauna and volcanic glass. The material is poorly sorted. Mineral character and texture indicate different origin than the rest of the sample made of Miocene clay. Sample MF7 contains neither microfauna nor volcanic glass. Its ceramic fabric includes large amounts of quartz pelite and is abundant in clastic material: fragments of rocks and mica (muscovite and biotite), it also includes numerous K-feldspars. It is in all probability from a regolith, developed on volcanic/igneous rock.

2.4.2 Admixtures

Three kinds of admixtures were registered in the fabrics, i.e. grog, sand and fragments of rocks. Only addition of grog is undoubtedly intentional. Sand and fragments of rocks could have originated either from the sediment (raw material) or may have been added purposely. The degree of rounding of the grains depends on the distance transport or is the result of many cycles of transport. Well-rounded grains of quartz might have originated from alluvial, beach or dune deposits.

Grog, as in many other cases, is clearly distinguishable in the ceramic fabrics. It is visible as regular crumbs with sharp edges, with its composition often differing from the loamy substance surrounding it. Certain less destructed fragments are dichromatic, characterized by two zones: oxidised surfaces and a darker core (Figure 7: E; Figure 8: D, E). Grog was registered in numerous samples, such as those from a pear-shaped vessel and jug (MF3, MF5), two pots (MF6, MF8, Figure 10) and a bowl (MF4). A small amount of grog temper was determined in a sample from a small bowl (MF1) and a jug of the Baalberge type (MF9, Figure 11).

The presence of sand in the ceramic fabrics is demonstrated by the content of rounded grains of quartz, polycrystalline quartz and occasionally K-feldspars in fabrics. This appeared in vessels such as a cup (sample MF2), a pear-shaped vessel, a jug (MF3, MF5) and a pot /MF8/ (Figure 4: C; Figure 5: D; Figure 7: E; Figure 10: F).

Temper made of crushed rock was registered in the fabrics of a pot and an amphora (MF6 and MF7). In sample MF6, these rock fragments derive mostly from angular feldspars, plagioclases, igneous rocks whereas the grains of quartz are well-rounded. In this case, most probably, the temper made of sand and crushed igneous rocks had been mixed with greasy Miocene clay. In sample MF7 (Figure 9) diverse crumbs of rocks are present: igneous, sedimentary, metamorphic. The fragments of grains of sedimentary and metamorphic rocks are usually rounded whereas the crumbs of igneous rocks are sharp-edged.

2.4.3 Kinds of ceramic fabrics

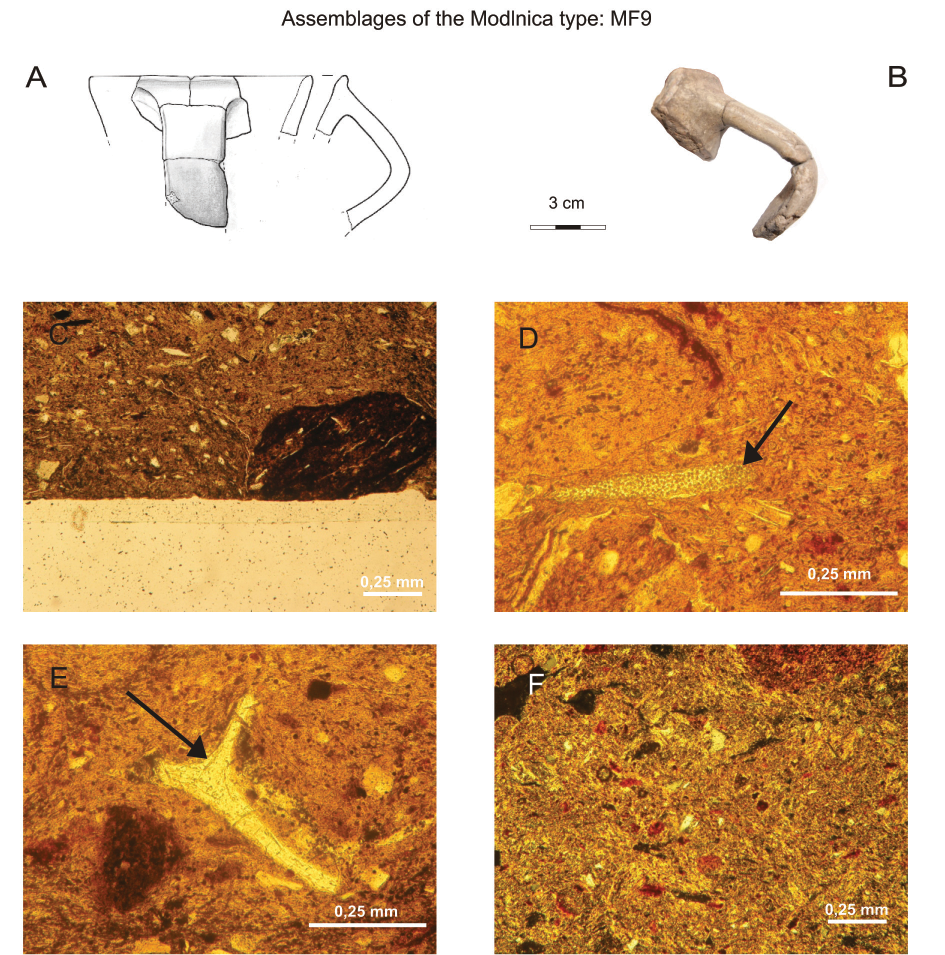

The ceramic fabrics of the analysed set of vessels differ in the composition and in the ratio of particular components. Separate samples are distinguished by their own unique character, although they have one thing in common, Miocene clay had been used in their ceramic fabric as one of the raw materials (apart from sample MF7 – Figure 13). Technological groups were established assuming that the raw material characterized by a specific composition had been used purposely. In general, we can mention two kinds of ceramic fabrics : “greasy”, containing more than 60% clay minerals (MF2, MF3, MF4, MF9) and “lean”, containing less than 60% of clay substance (MF1, MF5, MF6, MF7, MF8) (Figure 12).

Within the first group, the samples contain small quantities of quartz pelite and had been made of Miocene clay with an admixture of a considerable quantity of grog.

Within the second group, the samples are highly diverse, this is presented in a diagram (Figure 13). We can distinguish samples with a considerable amount of quartz pelite: deriving from a small bowl (MF1), a handle with a discoid application (MF7) and a pot (MF8) and samples with a small amount of this component: a jug (MF5) and a pot (MF6). A considerable quantity (circa 20%) of grog was registered in the fabrics of the latter two samples. In the fabrics of the jug (MF5) and the two pots (MF6, MF8), a substantial amount of relatively well-smoothed, larger grains of quartz and feldspars were noted. In the group of “lean” ceramic fabrics, two samples, from a pot (MF6) and a handle with a discoid application (MF7) also contained a temper of crumbs of igneous rocks.

In spite of all the differences in their compositions, the vessels of both groups demonstrate a relatively high quality of material preparation. Additionally, in comparison with the analysed pottery of the Malice culture and the Funnel Beaker culture the vessels in question are distinguished by extremely high quality, taking into consideration the fact that certain vessels of the Malice culture and the Funnel Beaker culture are characterized by considerable friability and brittleness. These kinds of features were not observed in the pottery deriving from assemblages of the Modlnica type. The problem of brittleness or friability could have affected vessels made of greasy ceramic fabrics, but taking into account the fact that this problem was not registered, we may assume that this group of pottery was well-fired. One sample, MF6 (from the jug of the Baalberge type with an elbow-shaped handle), indicates close affinities in ceramic fabric to the thick-walled funnel beakers of the Funnel Beaker culture and to a single analysed sherd of a vessel of the Wyciąże-Złotniki group (Rauba-Bukowska 2011). Its ceramic fabric is primarily composed of clay minerals and small amounts of grog, it does not contain any larger crystalline grains or fragments of rocks. The fabric is light brown. Certain diffuse, extremely fine-grained colourless substances were registered in the fabric, similar substances were also noted in the fabrics of the above-mentioned funnel beakers of the Funnel Beaker culture. The analysed fragments do not indicate any affinities to ceramic fabrics of vessels of the Malice culture (Rauba-Bukowska 2011) where the fabrics, depending on the use for which the vessel was intended, contain considerable amounts of quartz and other components containing clay; greasy fabrics (more than 60% clay minerals) are rare. In fabrics of the Malice culture vessels, organic material was registered, it having been in all probability a deliberate admixture.

No admixture of organic material into the ceramic fabric was noted within the analysed set of vessels from assemblages of the Modlnica type. In one case, in sample MF9, a fragment of organic material was noted, but this was of an accidental character. Among the analysed set of vessels from assemblages of the Modlnica type, raw materials with small amounts of quartz prevail. Only three vessels are characterized by a considerable quantity of quartz, although the provenance of the raw material in these three cases is different from the remaining vessels (MF1, MF7, MF8). The greasy fabric was tempered with both grog and sand. The fabrics are well-mixed and the lumpy character of the particular fabrics results from the admixture of crushed sherds. Micro-cracks of ceramic fabrics and separation of larger crumbs out of the clay background are rare.

2.5 Conclusions

The majority of the vessels had been made of Miocene clay material. In all probability clay deriving from the Carpathian region with no equivalents in local, sub-Cracovian exposures. This is indicated by the presence of microfauna and volcanic glass in the fabrics of the examined vessels.

The three vessels, the raw material has a different provenance. Sample MF1 reveals a close affinity with local raw material, sample MF7 had been made of regolith, while sample MF8 had been made of Carpathian raw material different from that in the other samples.

Within the ceramic fabrics three types of deliberate admixtures were distinguished: of grog, sand and crushed rock.

The fabrics of the smaller forms of vessels are usually greasy and do not contain any admixture of sand or crushed rock. They were only tempered with a small amount of grog. Larger forms had been made of raw material tempered with various admixtures.

Within the analysed set of vessels, one sample (MF9) bears certain resemblance to the technology of the Funnel Beaker culture and of the Wyciąże-Złotniki group of the Lengyel-Polgár circle.

Neither analogies nor similarities to the technology of vessel production typical of the Malice culture were registered.

All the types of vessels are characterized by well-mixed ceramic fabrics and are of high quality.

The technology of vessel production is based on:

– the use of diverse admixtures to clay,

– careful mixing of the mass,

– well-performed process of firing in conditions of limited inflow of air.

3. Inlay in incised ornamentation (Furchenstichkeramik) – research on the composition and

reconstruction of the production technique

3.1 Preliminary remarks

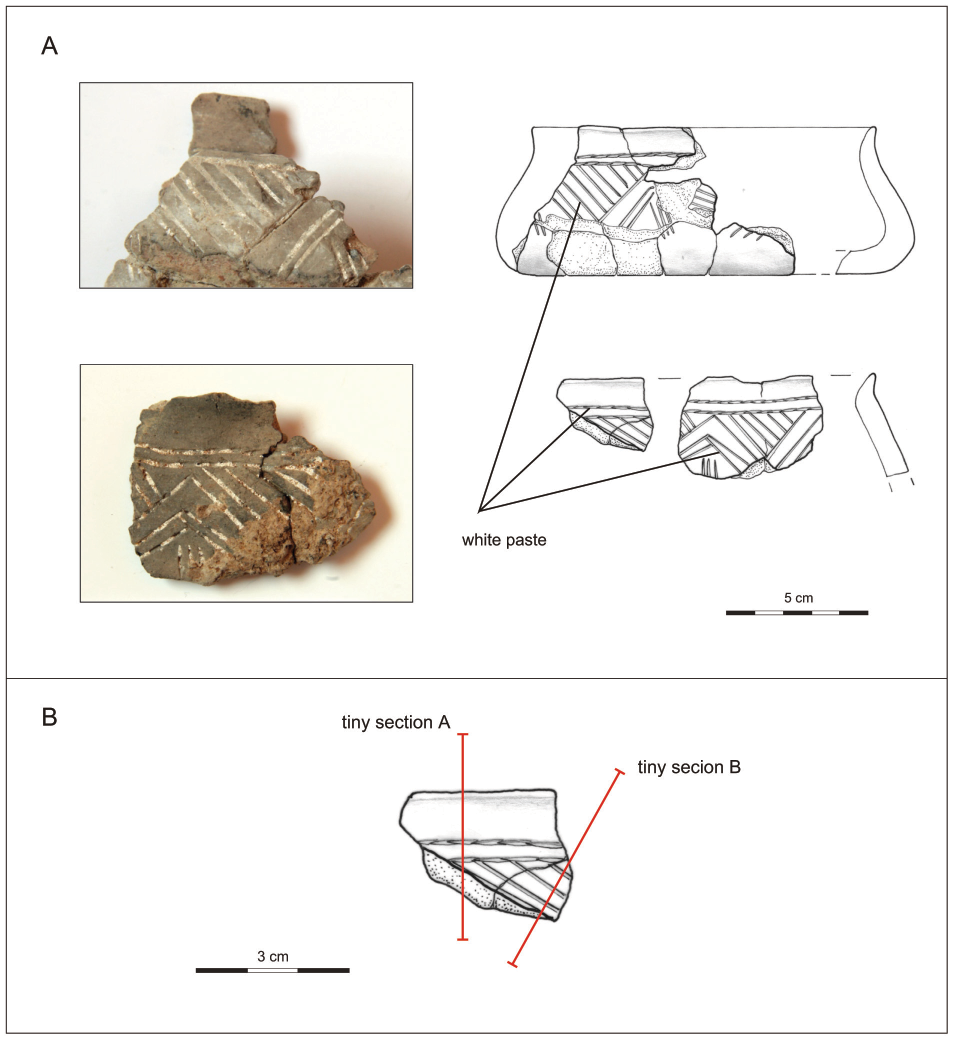

The matt, white inlay filling the grooves of the ornament (Furchenstich) on the surface of the miniature clay bowl was examined (Figure 14). The vessel in question is characterized by diversified decoration consisting of two lines of stab marks beneath the edge of the vessel and four oblique lines of engraved ornamentation, made in all likelihood with the same tool. The bowl derives from feature 4435 at site 5 in Modlnica near Kraków attributed to the Late-Neolithic (Eneolithic), the so-called assemblages of the Modlnica type (see: Zastawny, Grabowska in print). The objective of the research presented here is to determine the composition of the encrusting paste, determine the process of the manufacture of the inlay and reconstruct how the decoration had been put on the vessel.

3.2 Materials and methods

Thin sections were made from fragments of the rim of the miniature clay bowl with visible grooves of ornament 0.3 mm wide, filled with white inlay. They were denoted as cross-section A (through incised ornament) and cross-section B (through engraved ornament) (Figure 14). The thin sections were subjected to the following examinations:

– examination under a polarising microscope (PLM; Olympus BX51 microscope). The research was aimed at determining the composition of the white paste, the exact details regarding its production and preparation of the surface of the vessel

– observations with a scanning microscope with X-ray EDS microanalyser of X-radiation (SEM: NanoNova FEI Company device; EDS: Jeal). The research was aimed at supplementing the observations under the polarizing microscope and the determination of the chemical composition.

3.3 Results of the research

3.3.1 Observations under the polarising microscope

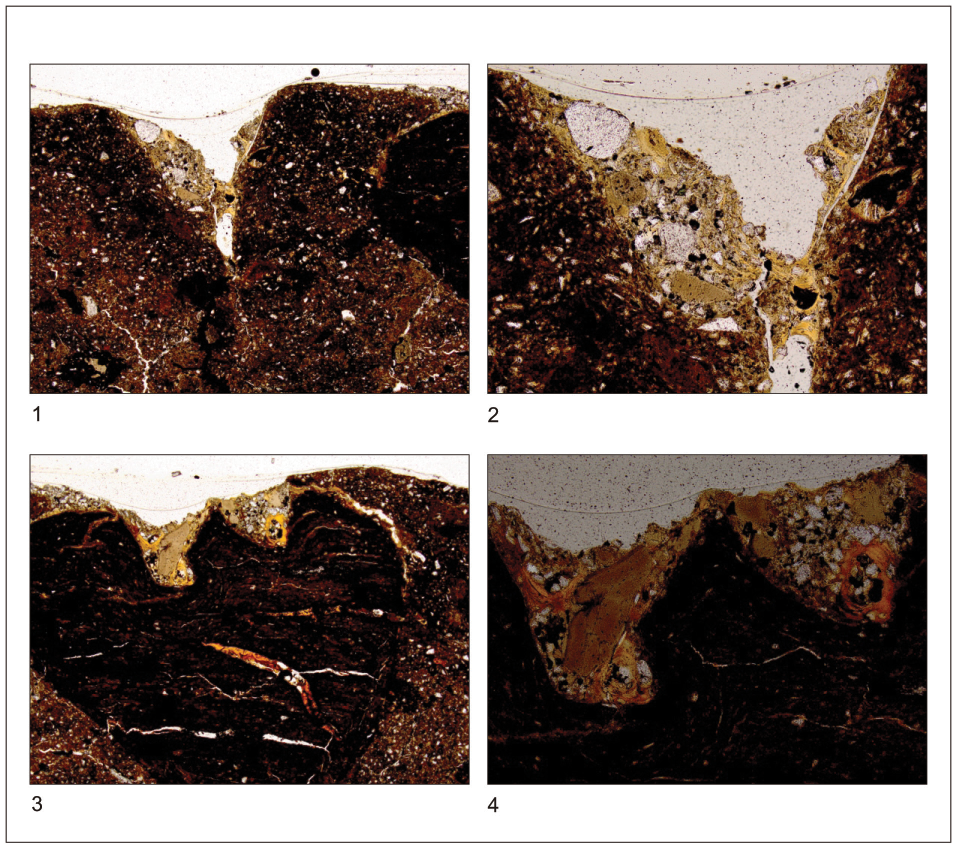

The grooves forming the ornament on the surface of the vessel are filled with a mixture of cuboidal grains in grey interferential colours, colourless under parallel polarizers and partly red- or brown-coloured. Structures characteristic of Haversian canals and osteones (bone tissues) are visible. The size of the grains is 0.3 mm on average, the grains had been sorted (although, of course, fine or coarse grains were observed, cf. Figures 15: 1-4; 16: 1-6). These are fragments of bone. The brown colouring of the grains demonstrates their heating.

The second component of the paste is constituted of platy minerals characterized by yellow interferential colours, yellowish under parallel polarizers. These are clay minerals with iron compounds the chemical composition of which (cf. below) suggests mixed layered minerals illit/smectit. They are widespread minerals, devoid of any particular characteristics. They may occur in the paste in quantity (Figure 16: 1, 2).

The third component of the paste may be constituted of (and in most cases, is constituted by) fine-grained quartz or/and feldspar (as a rule, co-occurring with clay minerals with this being their natural admixture; Figure 15: 1–4). In one of the paste samples (Figure 15: 2) a grain of quartz with a triangular cross-section was observed, such grains are encountered within loess deposits, occasionally in volcanic debris.

The fourth components are opaque, oval fine particles, as a rule of 0.01 mm size (although larger ones as well may occur; Figure 15: 2). These might have been of carbonized organic substance or deoxidized iron compounds.

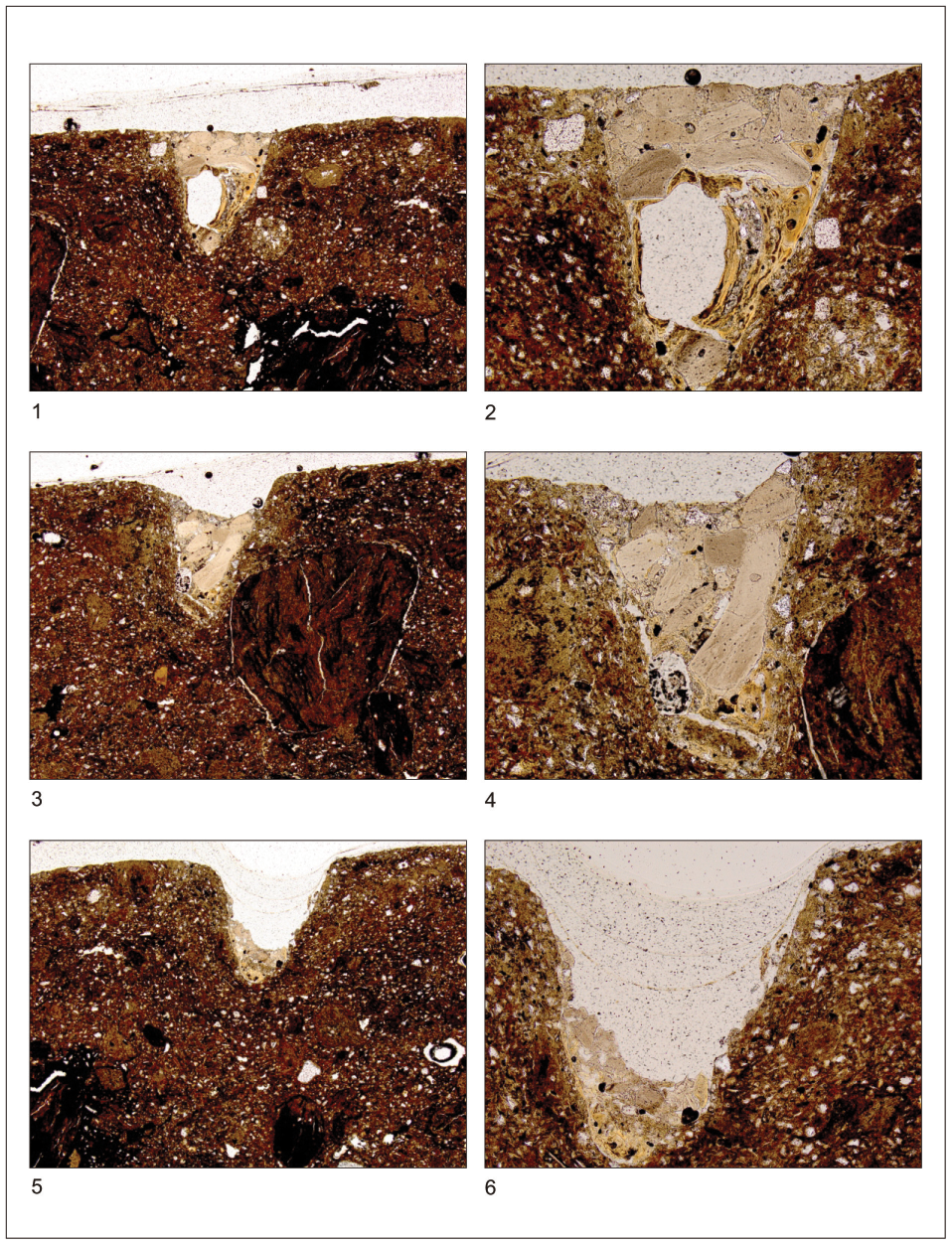

The area of contact of the paste with the ceramic fabric is distinct and of two kinds (even for the same groove, cf. Figure 15:2): either compact (which may suggest parching) or loose (not so intensive parching?). In the cross section the inlay is usually triangular in shape, although certain “flaws” may occur as well (Figure 15:3, 4). They are inserted in both the ceramic fabric and the soft grains of the temper (Figure 16). The surfaces of the areas of the inlaid ornament are extremely carefully smoothed (Figure 16: 1, 2), unfortunately, they are corroded in most cases (the inlay was chipped; Figures 15: 1–4; 16: 3–6).

The encrusting paste within different parts of the incised ornament has a different appearance. In some, numerous particles of bones are visible (Figure 16: 1, 2) whereas in others only isolated examples appear (here clay-quartz fabric prevails; Figure 16: 1–4). In certain cases, the presence of large pores is observed (Figure 16: 1–2). This results either from the viscosity of the paste fabric preventing filling of deeper parts of the incised decoration, or from the liberation of gases during the process of firing, for instance, as a result of the release of humidity or partial oxidation of organic components. On account of the shapes of the pores (oval) and the shape of the “stretched” laminas of clay minerals, the second hypothesis is perceived as more plausible.

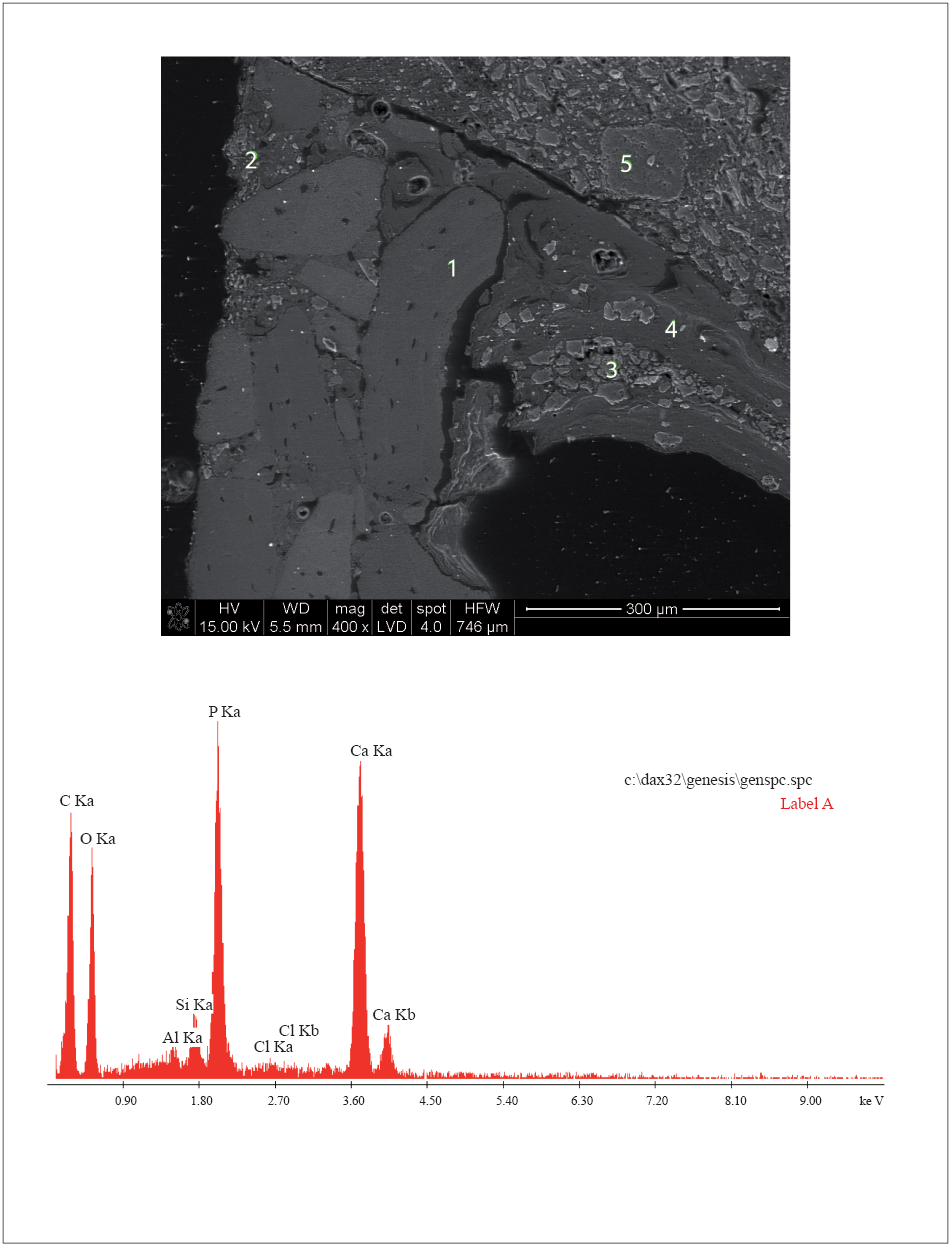

3.3.2 Observations under the scanning microscope with a chemical microanalysis

The contact with the surface of the vessel with encrusting paste is sharp. The paste consists of powder composed of calcium phosphate and aluminosilicates (Figure 17: 1, 2). The grains of crushed bone fit tightly, although it is hard to define if this is a result of either extremely careful “compacting” of the paste or particularly weak sintering of certain grains.

The encrusting material (referred to as “paste” below) is characterized by the following features:

· It was primarily made of crushed and calcined bones, the bone powder is distinguished by the cuboid shape of the grains of a similar length and height (on PLM picture – rectangular).

· Bone powder prevails in the paste within a number of grooves, although it does not within others. This is quite surprising, taking into consideration the fact that observations concern a single, small fragment of a sherd. We may therefore deduce that the paste was not homogeneous.

· Apart from bone powder, clays are present in the paste (or a mixture of clays and extremely fine-grained quartz or feldspar), intentionally applied. They have been detected at the bottom of a groove. It is possible that it was the “base coat” under the bone powder, helpful in filling the least accessible parts of the groove.

· Presumably, the bone powder and remaining mineral components were mixed with a water binder and/or with another organic substance to obtain the proper consistency of paste. The possibility of the admixture of an organic component may be verified by colourless particles diffused in the paste (esp. Figures 15:2; 16:2–6), not completely oxidized during the process of firing (cf. below).

· Most plausibly, the vessel decorated with paste was fired, although it is hard to define whether in the first or second event (when paste was placed into the grooves). An analysis of the phase composition of the bones (which means the determination of the firing temperature) would not have been helpful in such a case, as the bone could have been heated at a high temperature during the process of production of bone white pigment. The process of firing had caused gas infiltration into certain grooves (Figure 16: 1, 2) and the appearance of air bubbles therein. These gases could have originated from the release of humidity and oxidation of the organic components. The presence of carbon within the bone powder (Figure 17: 1, 2) may result from not heating the bone powder to an extremely high temperature (the process of oxidizing of organic component had not been completed) or from the secondary impregnation of the bone powder by carbon released during the process of firing from an organic substance used as a binder.

· Perhaps, during the process of firing, segregation of bone dust and clay had occurred. In such a case, it should be assumed that the grooves had been originally filled in one operation with paste consisting of bone powder and clays (or clay-quartz/feldspar).

It should be mentioned that all the grooves are asymmetrical. The features of the encrusting paste seem to be slightly different in the lines of stab marks made with a stylus (Figure 15) than in the engraved lines (Figure 16), in all probability made with the same, cuneate burin. In the latter, the quantity of crumbs of bone is higher, they are also more carefully “compacted”.

3.3.3 Reconstruction of the process of inlay manufacture

The process of inlay manufacture is believed to have been completed as follows:

· Sorted bone white pigment was produced by a process of heating bone at a high temperature in an oxygen atmosphere.

· The bone powder was mixed with clayey fabric (or clay-grainy mass) and with an organic or water binder to obtain the desired consistency of paste.

· Grooves were made on the hard (not necessarily fired) surface of a clay vessel. As a result of this, the edges of the grooves were smooth and even.

· The incised lines were filled with the inlay, perhaps at first with loamy mass, then with the bone powder?

· The surface of the vessel was carefully smoothed.

· The vessel was fired.

· The vessel was in use.

· As a result of corrosion processes (use, post-deposit processes?) part of the inlay was chipped.

3.4 Recapitulation

The encrusting inlay was made of powdered calcined bone, possibly bone white: a white pigment known from numerous cultures over a wide range of time (Eastaugh et al. 2004, 58). The bone powder was sorted and combined (not very carefully) with loamy materials, a natural mixture of loamy materials and fine grains of quartz and/or feldspars. These materials were in all probability mixed with a water binder or an organic substance to achieve the desired consistency of paste. The grooves made on the hard surface of the vessel were filled with paste, then the vessel was fired, although it is hard to define whether it was a hard firing process or aimed only at hardening of the paste. It was definitely not performed at a particularly high temperature. The paste is not durable and due to corrosion part of the inlay was chipped.

Future research on analogous material should be focused on individual features of encrusting fabric and analyses with reference to the kinds of grooves and the character of their ornamentation. The shapes of the stab marks are worth examining in a vertical projection. All these characteristics may be distinguishing features of a particular workshop or even of particular craftsmen.

Acknowledgements

The authors would like to thank the Kraków Team for Motorway Research (made up of the Institute of Archaeology and Ethnology of the Polish Academy of Sciences, the Archaeological Museum in Kraków and the Jagiellonian University in Kraków) for the opportunity to study the material and for financing the microscopic analyses of the Furchenstichkeramik presented in this article. The microscopic study on LBK pottery had been financed from the grant no. NCN, No. N N109 181040, headed by Agnieszka Czekaj-Zastawny, Institute of Archaeology and Ethnology Polish Academy of Sciences, Kraków. The authors also would like to express their gratitude to the reviewers (Maciej Pawlikowski and Marek Nowak) for helpful and fruitful comments to the text. Translated by Aleksandra Sabat-Maj.

References

BUKOWSKI, K., de LEEUW, A., GONERA, M., KUIPER, K., KRZYWIEC, P., PERYT, D. 2010: Badenian tuffite levels within the Carpathian orogenic front (Gdów-Bochnia area, Southern Poland): radioisotopic dating and stratigrafic position, Geological Quarterly 54/4, 449–446.

CZEKAJ-ZASTAWNY, A., RAUBA-BUKOWSKA, A. in print: Technologia i chronologia najstarszych naczyń glinianych w dorzeczu górnej Wisły (VI/V tys. BC). Archiwum Narodowego Centrum Nauki, Kraków.

EASTAUH, N, WALSCH, V., CHAPLIN, T., SIDDAL, R. 2004: The Pigment Compendium. A Dictionary of Historical Pigments. Elsevier Butterworth Heinemann, Oxford, 1–499.

LEXA, J., SEGHEDI, I., NÉMETH, K., SZAKÁCS, A., KONEČNÝ, V., PÉCSKAY, Z., FÜLÖP, A., KOVACS, M. 2010: Neogene-Quaternary Volcanic forms in the Catpathian-Pannonian Region: a review, Central European Journal of Geosciences 2 (3), 207–270.

JANÁK, V. 1993: Keramické památky typu Retz. In: Podborský, V. (Ed.): Pravĕké dĕjiny Moravy. Vlastivĕda moravská. Zemĕ a lid (N.Ř) 3. Brno 1993, 161–165.

KOVÁRNÍK, J. 2004: Vývoj na konci II. stupnĕ MMK/MOG a další otázky k počátku eneolitu. In: Kazdová, E., Mĕřínský, Z., Šabatová, K. (Eds.): K poctĕ Vladimíru Podborskému. Brno 2004, 113–121.

KOVÁRNÍK, J. 2008: Nové nálezy keramiky zdobné brázdĕným vpichem z jižní a jihozápadní Moravy. In: Cheben, I., Kuzma, I. (Eds.): Otázky neolitu a eneolitu našich krajín 2007. Nitra 2008, 141–157.

PAVÚK, J. 2004: Kommentar zu einen Rückblick nach vierzig Jaren auf die Gliederung der Lengyel-Kultur, Slovenská Archeológia 52, 2004, 139–160.

PAVÚK, J. 2001: Hausgrundriß und Furchenstichkeramik der Gruppe Bajč-Retz aus Čataj in der Slowakei. In: Roman, P., Diamandi, S. (Eds.): Cernavodă III – Boleráz. Stud. Danubiana Ser. Symposia II Bucureşti 2001, 563–578.

RAUBA-BUKOWSKA, A. 2011: Results of the microscopic analysis of Neolithic vessels and artifacts made of clay from Site 5 in Modlnica, Cracow district. In: Kruk, J., Zastawny, A. (Eds.): Modlnica 5, pow. krakowski – od środkowego neolitu po wczesną epokę brązu. Via Archaeologica, Kraków, 557–629.

RUTTKAY, E. 1999: Spätneolithikum. In: Lenneis, E., Neugebauer-Maresch, Ch., Ruttkay, E. (Eds.): Jungsteinzeit im Osten Österreichs. St. Pölten-Wien 1999, 108–204.

RUTTKAY, E. 2004: Eine neue Hakenspirale aus Purbach am Neusiedler See, VB Eisenstadt-Umgebung, Burgenland – Beitrage zur jungneolitischen inkrustierten Keramik (Furchenstichkeramik). In: Kazdová, E., Mĕřínský, Z., Šabatová, K. (Eds.): K poctĕ Vladimíru Podborskému. Brno, 141–155.

WENTWORTH, C. K. 1922: A scale of grade and class terms for clastic sediments, Journal of Geology 30, 377–392.

ZASTAWNY, A., GRABOWSKA, B., in print: The first in Lesser Poland settlement material with pottery decorated with needle etching ornament (Furchenstichkeramik) from Site 5 in Modlnica, Cracow district. In: Otázky neolitu a eneolitu našich krajín 2010. Vršatské Podhradie.

*Corresponding author. E-mail: zastawny@ma.krakow.pl

Figure 1. Modlnica, site 5, Kraków district. Location of the site and distribution of features with assemblages of the Modlnica type (with pottery decorated with the incised ornament – Furchenstichkeramik). Drawn by A. Zastawny.

Figure 2. Modlnica, site 5, Kraków district. Assemblages of the Modlnica type, the percentage content of the grains > 0,1 mm.

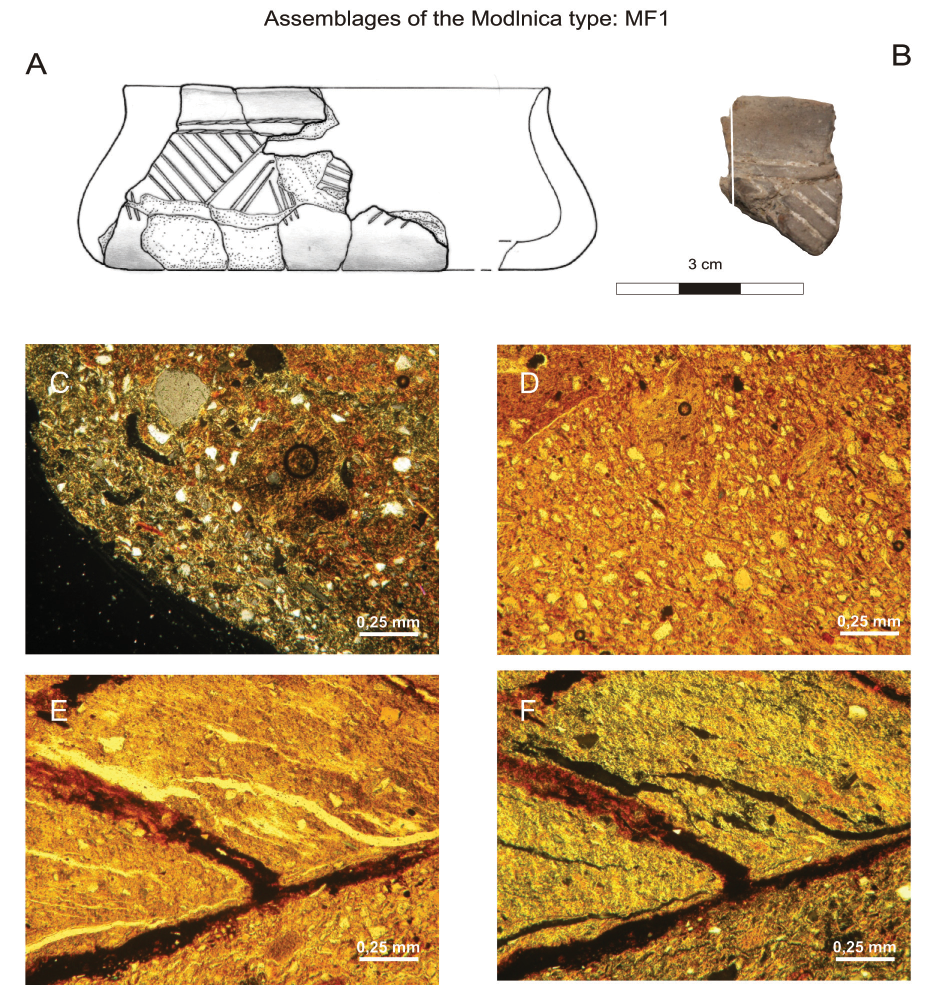

Figure 3. Sample no MF1 (feature 4435): A – reconstruction of the vessel, B – photo of the vessel fragment with the point where it was cut and marked, C – microscopic image of the pottery(XPL), the photo shows a dark-brown ceramic mass near the external surface of the vessel; D – microscopic image of the pottery (PPL), the photo shows a brown, “lean” ceramic fabric wherein well-sorted, fine-grained grains of quartz are visible, E – microscopic image of the pottery (PPL), F (XPL), the photo shows a fragment of schist with concentrations of iron oxides-hydroxides. Drawn by B. Grabowska, photo by A. Rauba-Bukowska.

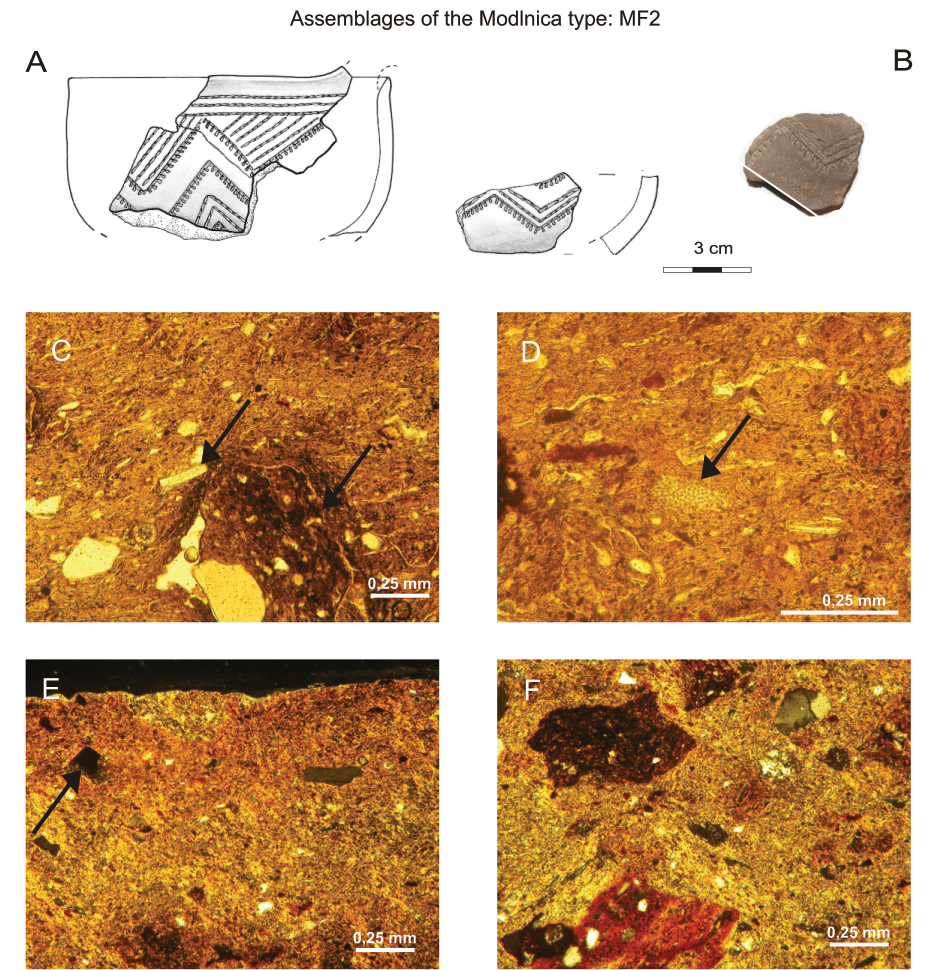

Figure 4. Sample no MF2 (feature 4435): A – reconstruction of the vessel, B – photo of the vessel fragment with the point, where it was cut and marked, C – microscopic image of the pottery (PPL), the photo shows the brown ceramic fabric wherein a dark crumb of grog (arrow on the right) and the regular fragment of volcanic glass (arrow on the left) are visible; D – microscopic image of the pottery (PPL), the photo shows the “greasy” ceramic fabric wherein the microfauna is noticeable (arrow); E – microscopic image of the pottery (XPL), the photo shows the external edge of the vessel, fragment of volcanic glass (arrow) and a few grains of quartz; F – microscopic image of the pottery (XPL), the photo shows dark fragments of grog and grains of quartz in loamy matrix. Drawn by B. Grabowska, photo by A. Rauba-Bukowska.

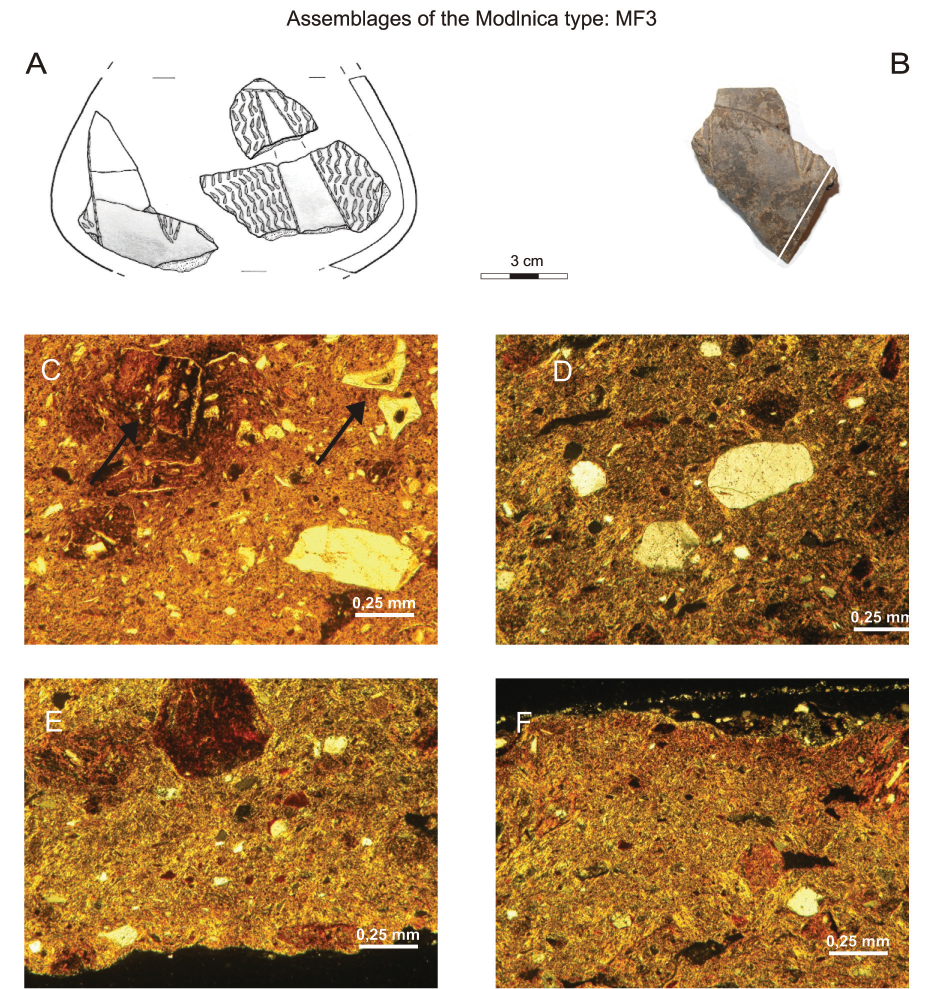

Figure 5. Sample no MF3 (feature 1661): A – reconstruction of the vessel, B – photo of the vessel fragment with the place where it was cut and marked, C – microscopic image of the pottery (PPL), the photo shows the brown ceramic fabric wherein: a crumb of grog (arrow on the left), two fragments of volcanic glass (arrow on the right) and a grain of quartz are visible; D – microscopic image of the pottery (XPL), the photo shows the “greasy” ceramic fabric wherein grains of quartz of different sizes are visible; E – microscopic image of the pottery (XPL), the photo shows a zone of the inner edge of the vessel; F – microscopic image of the pottery (XPL), the photo shows a zone of the external edge of the vessel. Drawn by B. Grabowska, photo by A. Rauba-Bukowska.

Figure 6. Sample no MF4 (feature 4435): A – reconstruction of the vessel, B – photo of the vessel fragment, C – microscopic image of the pottery (XPL), the photo shows the “greasy” ceramic fabric, in the area of the inner surface of the vessel; D – microscopic image of the pottery (PPL), the photo shows a “greasy” ceramic fabric wherein: crumbs of grog of different sizes, K – feldspar and fragment of volcanic glass (arrow) are noticeable; E – microscopic image of the pottery (PPL), the photo shows microfauna and a larger grain of quartz; F – microscopic image of the pottery (XPL), the photo shows dark crumbs of grog of different sizes as well as an isotropic fragment of volcanic glass andmicrofauna (in the middle). Drawn by B. Grabowska, photo by A. Rauba-Bukowska.

Figure 7. Sample no MF5 (feature 4435): A – reconstruction of the vessel, B – photo of the vessel fragment with the place where it was cut and marked, C – microscopic image of the pottery (PPL), the photo shows the inner edge of the vessel covered with a thin layer of different clay; D – microscopic image of the pottery (XPL), the photo shows the ceramic fabric wherein a larger, dark crumb of grog is visible; E – microscopic image of the pottery (XPL), the photo shows a grain of feldspar, a grain of quartz and a crumb of grog in a brown ceramic mass; F – microscopic image of the pottery (PPL), the photo shows relics of microfauna (in the middle). Drawn by B. Grabowska, photo by A. Rauba-Bukowska.

Figure 8. Sample no MF6 (feature 4435): A – reconstruction of the vessel, B – photo of the vessel fragment with the place where it was cut and marked, C – microscopic image of the pottery (PPLL), the photo shows two larger grains of K-feldspars; D – microscopic image of the pottery (XPL), the photo shows the ceramic fabric wherein a large, dark fragment of grog is visible; E – microscopic image of the pottery (PPL), the photo shows a larger, dichromatic crumb of grog and smoothed grain of quartz; F – microscopic image of the pottery (XPL), the photo shows a grain characterised by a granophyric texture – with an intergrowth of quartz and alkali feldspar (hypertrophy of quartz and feldspars). Drawn by B. Grabowska, photo by A. Rauba-Bukowska.

Figure 9. Sample no MF7 (feature 4435): A – reconstruction of the vessel; B – photo of the the vessel fracture; C – photo of the vessel fragment with the place where it was cut and marked; D – microscopic image of the pottery (XPL), the photo shows two grains of quartz next to the mica; E – microscopic image of the pottery (XPL), the photo shows the ceramic fabric rich in muscovite, within the fabric – a rounded grain of sandstone and smaller angular grains of quartz; F – microscopic image of the pottery (PPL), the photo shows grains of K- feldspar (on the right) and quartz (on the left); G – microscopic image of the pottery (PPL), the photo shows a grain of sandstone; H – microscopic image of the pottery (XPL), the photo shows an irregular crumb of rock composed of quartz, K- feldspar and micas and a grain of polycrystalline quartz (on the right); I – microscopic image of the pottery (XPL), the photo shows a grain of plagioclase (in the centre). Drawn by B. Grabowska, photo by A. Rauba-Bukowska.

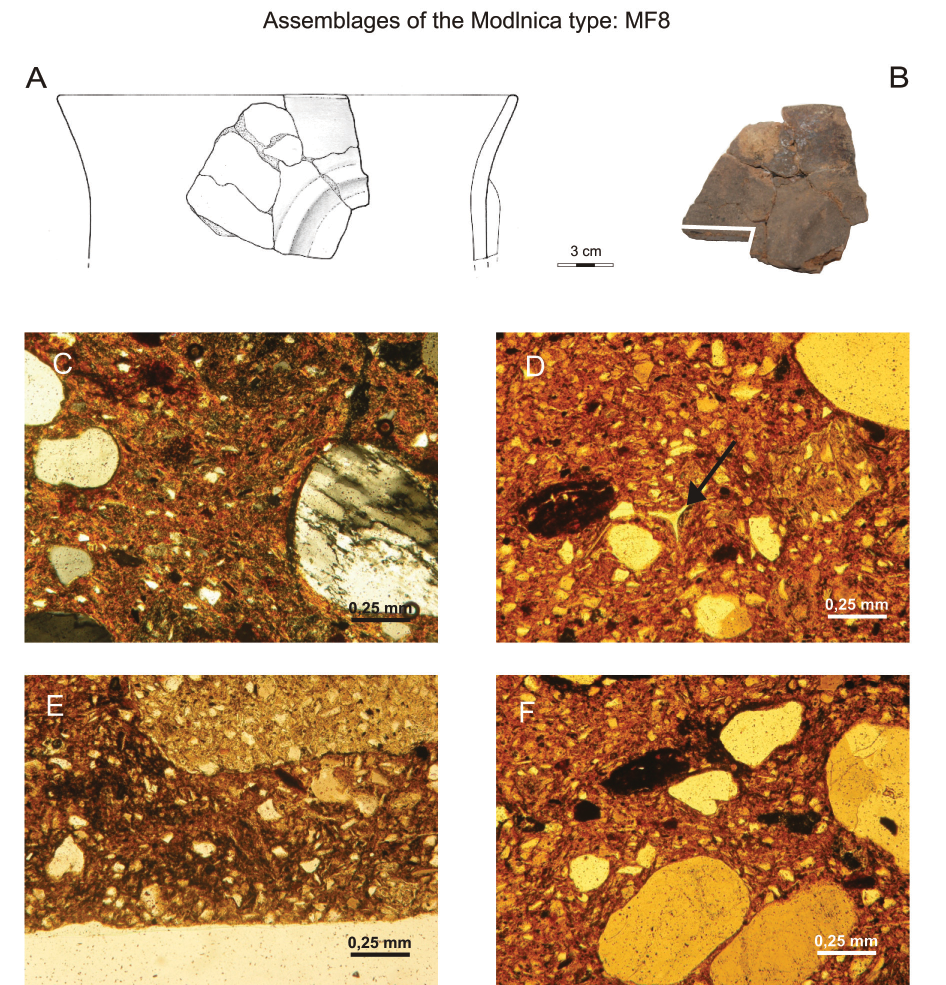

Figure 10. Sample no MF8 (feature 4435): A – reconstruction of the vessel, B – photo of the vessel fragment with the place where it was cut and marked, C – microscopic image of the pottery (XPL), the photo shows smoothed grains of quartz within the ceramic mass; D – microscopic image of the pottery (PPL), the photo shows a “lean” ceramic fabric wherein grains of quartz of different sizes and a fragment of volcanic glass (in the centre, indicated with an arrow) are visible; E – microscopic image of the pottery (PPL), the photo shows the inner edge of the vessel. A regular crumb of grog is noticeable in the upper part; F – microscopic image of the pottery (PPL), the photo shows a ceramic fabric wherein grains of quartz of different sizes are visible. Drawn by B. Grabowska, photo by A. Rauba-Bukowska.

Figure 11. Sample no MF9 (feature 1601): A – reconstruction of the vessel, B – photo of the vessel fragment with the place where it was cut and marked, C – microscopic image of the pottery (PPL), the photo shows a “greasy” ceramic fabric in the zone of the inner surface of the vessel; D – microscopic image of the pottery (PPL), the photo shows relics of microfauna surrounded by clay matrix (arrow); E – microscopic image of the pottery (PPL), the photo shows a fragment of volcanic glass (arrow); F – microscopic image of the pottery (XPL), the photo shows a general view of the homogeneous ceramic mass. Drawn by B. Grabowska, photo by A. Rauba-Bukowska.

Figure 12. Modlnica, site 5, Kraków district. Assemblages of the Modlnica type, correlation of three features of ceramic fabrics: content of clay minerals, content of quartz and content of grog. The values are expressed as percentages.

Figure 13. Modlnica, site 5, Kraków district. Assemblages of the Modlnica type,a diagram representing the composition of the most important components in the ceramic fabrics of vessels. The figures stand for the numbers of the samples.

Figure 14. Modlnica, site 5, Kraków district. Assemblages of the Modlnica type: A – a fragment of a miniature bowl decorated with an incised ornament (Furchenstich) and white paste encrustation (Zastawny, Grabowska 2011), B – a fragment of the vessel under analysis with highlighted cross-sections of thin sections. Photo by A. Zastawny, drawn by B. Grabowska.

Figure 15. Modlnica, site 5, Kraków district. Assemblages of the Modlnica type: a fragment of a miniature bowl decorated with an incised ornament (Furchenstich) and white paste encrustation (cross-section A through incised ornament – cf. Figure 14.): microphotographs made under a plane polarised microscopy (all the photographs were made with parallel polarisers, the photographs in the left column were made at a magnification of 1×40, in the right – 1×100).

Figure 16. Modlnica, site 5, Kraków district. Assemblages of the Modlnica type: a fragment of a miniature bowl decorated with an incised ornament (Furchenstich) and white paste encrustation (cross-section B through engraved decoration – cf. Figure 14.): microphotographs made under a plane polarised microscopy (all the photographs were made with parallel polarisers, the photographs in the left column were made in magnification of 1×40, in the right – 1×100).

Figure 17. Modlnica, site 5, Kraków district. Assemblages of the Modlnica type: a fragment of a miniature bowl decorated with an incised ornament (Furchenstich) and white paste encrustation. Microphotography SEM and microanalyses EDS in points: 1 – Calcium (Ca) and phosphorus (P) indicate a bone, 2 – grain of quartz, 3 – potassium- sodium aluminosilicate: clayey mineral, 4 – aluminosilicate with a small quantity of potassium and magnesium: clayey mineral, conceivably kaolinite, 5 – grain of quartz.

Table 1. Modlnica, site 5, Kraków district. List of samples of the assemblages of the Modlnica type selected for mineralogical and petrographic research.

|

Item number |

Symbol of the sample |

Number in the inventory |

Site |

Culture |

Location of the sample at the site |

Part of the vessel |

Type of pottery |

|

1 |

MF1 |

MOD-10836 |

Modlnica 5 |

assemblages of the Modlnica type |

feature 4435 |

rim |

bowl |

|

2 |

MF2 |

MOD-10843 |

Modlnica 5 |

assemblages of the Modlnica type |

feature 4435 |

the lower part of the belly |

cup |

|

3 |

MF3 |

MOD-7653 |

Modlnica 5 |

assemblages of the Modlnica type |

feature 1661 |

the lower part of the belly |

pear-shaped vessel |

|

4 |

MF4 |

MOD-10836 |

Modlnica 5 |

assemblages of the Modlnica type |

feature 4435 |

rim |

bowl |

|

5 |

MF5 |

MOD-10837 |

Modlnica 5 |

assemblages of the Modlnica type |

feature 4435 |

neck |

jug of the Baalberge type |

|

6 |

MF6 |

MOD-10836 |

Modlnica 5 |

assemblages of the Modlnica type |

feature 4435 |

the fragment of the belly below the neck |

pot with a handle decorated with a shield |

|

7 |

MF7 |

MOD-10836 |

Modlnica 5 |

assemblages of the Modlnica type |

feature 4435 |

belly with a handle |

the frg. of the amphora with a handle decorated with a shield |

|

8 |

MF8 |

MOD-10836 |

Modlnica 5 |

assemblages of the Modlnica type |

feature 4435 |

neck |

pot with a plastically formed band in the shape of “U” turned upside down |

|

9 |

MF9 |

MOD-7501 |

Modlnica 5 |

assemblages of the Modlnica type |

feature 1601 |

neck |

jug of the Baalberge type |

Table 2. Modlnica, site 5, Kraków district. Macroscopic features of potsherds of the assemblages of the Modlnica type.

|

Item number |

Symbol of the sample |

Thickness of the wall |

Ornament |

Type of the outer surface and its colour |

Fracture, color of the core |

Type of the inner surface and its colour |

Admixture |

Kind of a shard (soft/hard/brittle) |

Figure |

|

1 |

MF1 |

7 mm |

needle etching ornament, encrustation |

smooth, light grey |

monochromatic, bright grey-orange |

smeared, light grey |

visible |

hard |

Fig. 7 |

|

2 |

MF2 |

8 mm |

needle etching ornament |

smooth, brown |

dichromatic, grey |

smooth, grey |

visible |

hard |

Fig. 8 |

|

3 |

MF3 |

7 mm |

needle etching ornament |

smooth, dark brown |

tricoloured, dark grey |

smooth, brown |

visible |

hard |

Fig. 9 |

|

4 |

MF4 |

6 mm |

lack |

smooth, brown-orange |

tricoloured, dark grey |

smooth , brown-orange |

invisible |

hard |

Fig. 10 |

|

5 |

MF5 |

7 mm |

lack |

smooth, dark grey |

monochromatic, dark grey |

smooth, dark grey |

visible |

hard |

Fig. 11 |

|

6 |

MF6 |

6 mm |

plastically formed (a shield) |

smooth, light orange-brown |

dichromatic, grey |

rough, grey |

visible |

hard |

Fig. 12 |

|

7 |

MF7 |

7 mm |

plastically formed (a shield) |

slightly rough, brown |

dichromatic, gradual transition from orange to grey-orange |

rough, dark brown |

visible |

hard |

Fig. 13 |

|

8 |

MF8 |

8 mm |

plastically formed |

smooth, grey |

monochromatic, orange |

smooth, grey |

visible |

hard |

Fig. 14 |

|

9 |

MF9 |

7 mm |

lack |

smooth, cream-coloured (light orange) |

tricoloured, grey |

smooth, brown |

invisible |

hard |

Fig. 15 |

Table 3. Modlnica, site 5, Kraków district. Assemblages of the Modlnica type, mineral and petrographic composition of thin sections made from fragments of vessels. The values are expressed as percentages.

|

Symbol of the sample |

Loamy minerals |

Quartz |

Flint/ chalcedony |

K-feldspars |

Plagioclases |

Frg. Of sedimentary rocks |

Frg. Of igneous rocks |

Frg. Of metamorphic Rocks |

Muscovite |

Biotite |

Opaque minerals |

Chamotte |

Volcanic glass |

Heavy minerals |

Organic materials |

|

MF1 |

52 |

38 |

0 |

0 |

0 |

0 |

0 |

0 |

1.2 |

0 |

5.8 |

1.2 |

0.3 |

1.5 |

0 |

|

MF2 |

78 |

12 |

0 |

0 |

0.6 |

0 |

0 |

0 |

2.5 |

0 |

1.2 |

5.5 |

0.2 |

0 |

0 |

|

MF3 |

69 |

12 |

0 |

0.7 |

0 |

0 |

0 |

0 |

0.4 |

0 |

2.5 |

13.6 |

1.4 |

0.4 |

0 |

|

MF4 |

60 |

17.5 |

0 |

0.5 |

0 |

0 |

0 |

0 |

3 |

0 |

1.4 |

16.6 |

0.5 |

0.5 |

0 |

|

MF5 |

50 |

21.5 |

0 |

0.4 |

0 |

0 |

0 |

0 |

2.6 |

0 |

6 |

19 |

0.5 |

0 |

0 |

|

MF6 |

50 |

20 |

0 |

0.4 |

0 |

0 |

6.4 |

0 |

1.4 |

0 |

0.4 |

20.4 |

1 |

0 |

0 |

|

MF7 |

34 |

29.8 |

0.4 |

2.5 |

0 |

0 |

14 |

0 |

9 |

0.9 |

9 |

0.4 |

0 |

0 |

0 |

|

MF8 |

45 |

32 |

0 |

1 |

0 |

0 |

0 |

0 |

0.4 |

0 |

3.6 |

16.7 |

0.9 |

0 |

0.4 |

|

MF9 |

71 |

11.4 |

0 |

0 |

0 |

0 |

0 |

0 |

0.5 |

0 |

6.7 |

10 |

0.4 |

0 |

0 |

Table 4. Modlnica, site 5, Kraków district. Assemblages of the Modlnica type, results of granulometrical analysis of thin sections made from fragments of vessels. The values are expressed as percentages.

|

Symbol of the sample |

0.015-0.06 mm |

0.06-0.1 mm |

0.1-0.2 mm |

0.2-0.4 mm |

0.4-1 mm |

1-2 mm |

>2 mm |

|

MF1 |

90 |

6 |

2 |

1.6 |

0.4 |

0 |

0 |

|

MF2 |

74 |

18 |

4 |

3.5 |

0.5 |

0 |

0 |

|

MF3 |

70 |

14 |

9 |

5 |

1 |

1 |

0 |

|

MF4 |

59 |

13 |

14 |

7 |

7 |

0 |

0 |

|

MF5 |

72 |

13 |

6 |

5 |

3 |

1 |

0 |

|

MF6 |

75 |

16 |

3 |

3 |

2.6 |

0.2 |

0.2 |

|

MF7 |

56 |

24 |

13 |

4 |

2 |

1 |

0 |

|

MF8 |

85 |

5 |

4 |

4 |

2 |

0 |

0 |

|

MF9 |

80 |

11 |

4 |

1 |

4 |

0 |

0 |