Volume III ● Issue 2/2012 ● Pages 229–235

An Analysis of Metalworking By-products from the Medieval Town of Uničov

Martin Moníka*, Pavel Šlézarb

aDepartment of Geology, Faculty of Science, Palacky University, 17. Listopadu 12, 771 46, Olomouc, Czech Republic

bNational Heritage Institute, Michalská 3, 771 00, Olomouc, Czech Republic

Article info

Article history:

Received: 6 November 2012

Accepted: 23 December 2012

Key words:

Middle Ages

metalworking

Uničov

slags

optical microscopy

SEM-EDX, XRF

Abstract

Over the course of archaeological rescue excavations in the years 2009 and 2010, the remnants of metalworking processes in the form of slags and cast metal droplets were recorded in the town of Uničov. Analyses of thin sections, along with SEM-EDX and XRF analyses were carried out. The results indicate that the slags in all probability originated from iron smithing whereas the metal droplets arose from base metal processing. The results are in accordance with written sources which identify Uničov as a mining district centre as early as the 1st half of the 13th century.

1. Introduction

Uničov, situated in the Upper Moravian ravine (Figure 1) in the Czech Republic, has been a well-known metal-processing town since at least the High Middle Ages. New findings related to metalworking were discovered in the town over the course of archaeological rescue excavations in 2009 and 2010. The medieval artefacts produced by local workers were analysed using a range of laboratory methods. The results, along with a brief history of metalworking in the area, are presented below.

1.2 A brief history of metalworking in the Uničov area

The founding of Uničov in 1213 was undoubtedly influenced by its favourable position in the Upper Moravian depression, at the crossroads of ancient roads in close proximity to a ford on the Oskava River. The main reason for the founding was to increase the population in the area known for iron and non-ferrous ore deposits. Mining and working of iron had been practised in the area since at least the 8th century when Slavic ironmongery exploited the local haematite-magnetite Lahn-Dill ores of the Devonian age. In a well-known iron-working workshop at Želechovice, 2 km SE from Uničov in the Na Loukách area, 24 furnaces had been hollowed into sloping loess deposits at the Oskava River (Schirmeisen 1943, 53–56). An ironworking battery operated here in the 8th and the 1st half of the 9th century (Hlubek 2010; Klápště 2005, 297–298; Lutovský 2001, 381; Měřínský 2002, 305–318; Pleiner 1955; 1958; 2000), possibly supplying the pre-Great Moravian centre Povel in present-day Olomouc (Bláha 1988, 168). The expansion of the Mojmír dynasty to the Olomouc, Litovel, and Uničov areas may have also been influenced by the occurrence of local strategically important iron ore deposits.

Iron sponge produced by the furnaces was processed at the Želechovice workshop, formed into so-called iron bloom and subsequently transported to smithies for further processing. Certain pieces of iron were also shaped into axe-shaped ingots to serve as a pre-monetary means of exchange and used over a wide territory (Lutovský 2001, 97–99).

In Dolní Sukolom, 2 km north of the Želechovice workshop, a group of three iron smelting furnaces of the Želechovice type were hollowed into the loess terrace (Schirmeisen 1943). Although without dating material, the construction technology of the furnaces points to the 8th–9th centuries as well. In Žerotín, 6 km SE of Uničov, two iron smelting furnaces along with slags, tuyeres, and pottery from the 9th century were discovered at a later point (Ludikovský 1960). A shaft furnace mentioned from Brníčko, 17 km NW of Uničov, found along with a tuyere and several pieces of slags, was originally dated to the 11th–12th centuries (Pleiner 1958), although recent observations point rather to the 13th century. Further undated findings were made in Dlouhá Loučka, and in the Zlaté Návrší area, 5 km NE of Uničov (Goš 1988, 186).

Over the course of structural social changes in the 13th century, the Jeseníky Mountains, whose foothills lie no farther than 10 km NE from Uničov, became a key area for metal ore exploitation. Moravian margrave not only occupied the gold mines of the bishops of Wroclaw (Kouřil et al. 2000, 420) but also encouraged the rapid urbanization of the area to support their claim. In this manner, the towns of Bruntál (Freudenthal; before 1213), Uničov (Mährisch Neustadt; 1213), Hlubčice (Leobschütz; before 1222) and Opava (Troppau; between 1213 and 1220) were founded. The burghers of Opava commanded the silver and lead mines in the vicinity of Horní Benešov (Bennisch) as early as 1271, and exported lead ingots to Hungary through Uherský Brod (Ungarisch Brod). The silver from the Jeseníky Mountains also served for the minting of Opavian coins (Kouřil 2006, 39; Wihoda 2009, 168–169). The Zlaté Hory (Zuckmantel) area, Suchá Rudná (Dürrseifen), Vrbno pod Pradědem (Würbenthal), Stříbrné Hory (Neufang), Horní Město (Bergstadt), the Hankštejn (Hangenstein) and the Horní Benešov (Bennisch) areas (Karel 2011; Novák 1990; Večeřa 2002; Novotný, Zimák 2003) ranked among the most significant mining centres in the Jeseníky Mountains. According to estimates by J. Novák (1990, 42), 1.5 tonnes of gold and 22.2 tonnes of silver were exploited from these deposits in the High Middle Ages (see also Fojt, Voda 2011; 2012).

The actual town of Uničov was founded “by word of mouth”; the conditions of the appearance of this new town agglomeration (nova vila), as well as its rights and liberties are explained, however, in a newer document issued in Brno (Brünn) by Ottokar I in 1223. This so-called “Uničov list” is the first known town privilege in the Czech Lands (CDB II, V-246, 237–239). The mining district of Uničov was codified by margrave Přemysl in a charter which granted the burghers of Uničov new liberties and confirmed the old ones in 1234 (CDB III/1, V-76, 82–83). This document is the oldest codification of a mining district in the Czech Lands. The district ranged from the Czech-Moravian border to the middle course of the Moravice River and from there to the middle course of the Bystřice River. All the metals found in this territory belonged, with the exception of the areas belonging to the margrave, to the burghers of Uničov. The town was thus granted the profits of mining activities.

In order to better control the collection of mining fees, the margrave and the town decided to concentrate all the miners in the mining villages. One of these, dated to the 1st half of the 13th century, was discovered through an archaeological rescue excavation on Bezručova Street in Rýmařov (Römerstadt). It consisted of an irregular grouping of partially sunk buildings situated between mining works, e.g. grooves for gold washing. Amongst other things, a waste rock heap and the remains of a gold washing trough were discovered here (Goš, Karel 2003; Karel 2010). Frankštát (Frankenstadt, today’s Nový Malín), founded in the 13th century as a fortified mining town, also belonged to the mining district of Uničov along with the placer-mining sites at the Oskava River and the mines of Hankštejn. The latter yielded precious (gold-bearing quartz and silver-bearing galena), lead-zinc, copper, and iron ores. Mining took place in the proximity of Stříbrné Hory (Neufang), Horní Město (Bergstadt), Břevenec, and Ruda (Rambousek, Řepka 2009; Spurný 1972, 5–6; Karel 2011). Rešov castle, situated 6.5 km SW of Rýmařov, was built in order to protect the mines around Hankštejn.

New evidence of metalworking in Uničov was obtained in 2010 upon discovering two cast metal droplets on Olomoucká Street, i.e. at the periphery of the medieval town where the smiths were usually driven to. One of these fragments bore obvious imprints of a pottery crucible. The finds belong to the foundation horizon of the town, i.e. the 1st half of the 13th century. A battery of pear-shaped pit furnaces with an entrance pit were found and dated to the 13th century (Plaštiaková 2009) on Nemocniční Street. Slag fragments found at Bezručovo náměstí Square bear witness to smelting or smithing processes, as well as slags, ore fragments, and iron casts found earlier on Olomoucká Street (Michna 1980, 170; Šlézar, in press). Finally, an accumulation of 13th century slags was found on Masarykovo náměstí Square, NW of the town hall of Uničov, in 2009 (Faltýnek et al. 2010).

2. An outline of the material and methods

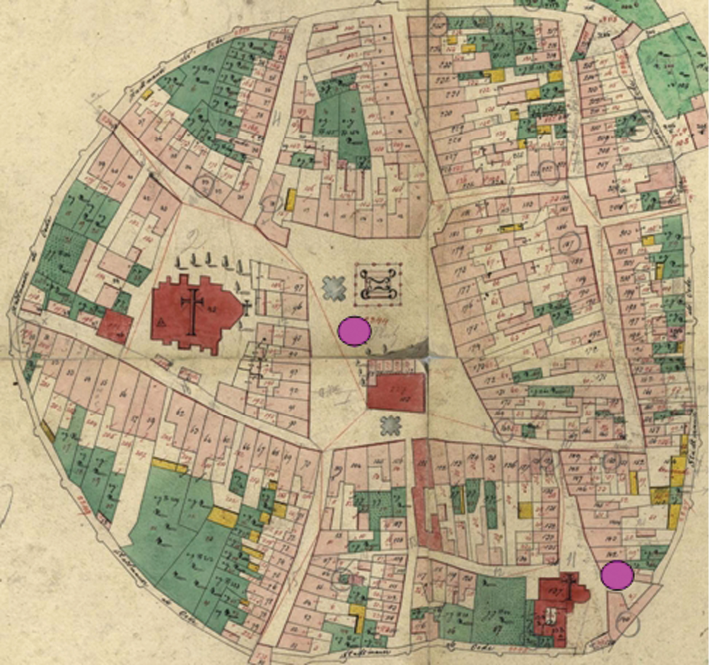

The material analysed in this paper originates from the above-mentioned rescue excavations on Masarykovo náměstí Square and on Olomoucká Street in 2009 and 2010 (Figure 2). The material was discovered along with pottery fragments dated to the 1st half of the 13th century, i.e. to the foundation horizon of the town of Uničov. The slags in all probability did not lie in their original position on Masaryk Square but were more likely removed here to stabilize the surface of the medieval square. Such a utilization of slag was evidenced in other medieval towns as well (Merta, Peška 2002). Out of the total 22 kg of slag, three macroscopically different pieces (described below) were selected and cut to make thin-sections. The samples were chosen large enough so that their size did not influence the magnetic susceptibility measuring. The thin-sections were consequently analysed with an optical polarizing microscope to determine their mineral composition. One of the sections (sample no. 1) was also submitted for SEM-EDX analysis with a JEOL JSM-6490LV electron microscope operating at the Department of Geology in Brno.

The magnetic susceptibility (MS, κ) was measured in all three slag pieces as well using a portable KT-6 kappameter. Each piece was measuered three times, the resulting average was the final magnetic susceptibility. Two more or less flat surfaces and the surface originated when cutting the sample for thin-sections were used for the measuring. In portable kappameter measuring, the results are always negatively influenced by irregularities in the artifact’s surfaces. For the analyses of archaeological artifacts, however, the portable device is more practical than more sophisticated laboratory kappameters (e.g. the KLY-4 device). Results are given in SI units in concordance with other petrographic MS analyses (e.g. Bradák et al. 2009; Zmeškalová et al. 2010).

The cast metal droplets found on the Olomoucká Street were analysed using the X-ray spectrometry (XRF) with the help of a DELTA Premium (Innov-X, Inc., USA) portable spectrometer operating at the Department of Geology in Olomouc. Voltages of both 15 and 40 kV were used for the measurements. The two droplets were analyzed whole, without further preparation. The PXRF instrument was mounted to a special table and the samples to a sample holder. The X-ray beam was then focused on the area of approximately 10 mm in diameter for each sample and the secondary X-rays were measured on Si(Li) detector.

3. Results of the analyses

3.1 Slags

The three slag fragments differed from each other macroscopically. Sample no. 1 (Figure 3) is a massive piece covered with limonite, with remnants of wooden fragments fused on the surface. Sample no. 2 (Figure 4) is more porous, with a lower content of limonite. Sample no. 3 (Figure 5) has a fluid-like surface indicating the rapid cooling of the molten material. Secondary limonite may also be observable in its folds. The magnetic susceptibility differed among the three samples although this might have been caused by the different mass of each sample (cf. Hrubý et al. 2006). The highest value was measured in sample no. 1 (7.62×10–3 SI), smaller values were evidenced in samples no. 2 (3.75×10–3 SI) and no. 3 (3.74×10–3 SI).

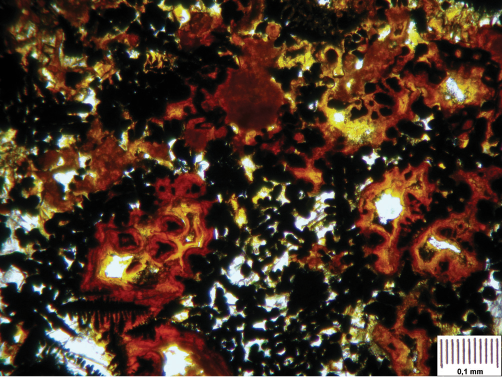

In terms of mineral composition, the samples were virtually identical. All were comprised of silicate glass and crystallized ferrous olivine fayalite (Fe2SiO4), wüstite (FeO), and secondary limonite, i.e. a mix of iron oxides and hydroxides. The fayalite forms laths of up to 0.5 mm in length. It is well developed above all in the pores formed during the slag cooling process. The interference colours of the fayalite range from bright yellow and orange to blue, green and pink (Figure 6). The wüstite mineral phase forms opaque dendrites and globules of up to 0.5 mm in length. Its higher refractive index causes it to step out of the glass-fayalite matrix (Figure 6). The glass phase is optically isotropic and more easily observable in reflected than in plane- and cross-polarized light. After cooling, the pores formed in the glassy matrix were partially filled with rusty brown limonite (Figure 7). This mix of iron oxides and hydroxides in all probability also conserved the microscopic organic materials, possibly the remnants of wooden fuel (Figure 8).

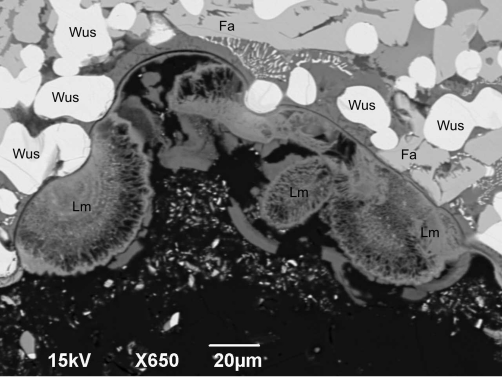

A SEM-EDX analysis of the mineral phases within sample no. 1 has confirmed the predominance of the fayalite phase over the kirschsteinite, monticellite, tephroite, and forsterite olivine phases (Table 1). The relative purity of the wüstite phase, containing only a small amount of aluminium along with iron and oxygen, has been demonstrated as well. The glass matrix is composed above all of silicite oxide, a smaller amount of iron, aluminium, potassium, and calcium oxides; minor amounts of phosphorous, sodium, and manganese oxides have been evidenced as well. The absence of sulphur in the slag clearly demonstrates the use of charcoal, not bituminous coal, in the metalworking process (cf. Pleiner 2006, 110). The calcium may have come from the ore but possibly also from the ash or the walls of the smithing hearth or another manufacturing device. Its small amount indicates, however, that it was in all probability not added deliberately to the charge as a flux agent. The nature of the metalworking process which took place on Masaryk Square in the Middle Ages has been also clarified by the SEM-EDX analysis, as small fragments of reduced iron within sample no. 1 could be observed under high magnification (Figure 9).

3.2 Metal droplets

The X-ray (XRF) spectrum of metal droplets from Olomoucká Street in Uničov showed that one patinated piece (sample no. 4) is a bronze-like alloy with an unusually high amount of tin (61.6% of Cu, 34.29% of Sn, 2.15% of Pb and 1.36% of Si – in wt%, normalized to 100%). It has to be stressed, however, the corrosion process in bronze artefacts often leads to decuprification of the outer patinated layer (Alberghina et al. 2011). This causes a disproportion between the original and the present Sn/Cu ratio. The high amount of tin in the Uničov sample thus should not be overestimated. The second droplet (sample no. 5; Figure 10) found nearby is made of almost pure lead (95.1%) accompanied by a small amount of silicium (3.04%) and 0.95% of aluminium.

4. Discussion

The absence of non-ferrous metals and the presence of reduced iron in the slags from Masaryk Square in Olomouc indicate that ironworking processes took place in the newly founded Uničov. The mineral phases of fayalite-wüstite are also typical for the ironworking slags. The problem of distinguishing between smelting and smithing slags is more difficult to solve as the material had been in all probability removed from its original context. Magnetic susceptibility measuring can be useful here, however, and the values measured in the analysed material are considerably high. This fact speaks for smithing production along with abundant wüstite in the slag matrix and the absence of minerals proceeding from waste rock (leucite, anortite etc.). Smelting slags, found, for example, in the Hostýn Hills, usually have lower values of magnetic susceptibility and still contain mineral phases originating in the waste rock (cf. Zmeškalová et al. 2010).

Although the slag material had been removed from its original context, we may still assume that the smithing furnace was situated in the centre of the medieval town. This may be corroborated by similar findings of slag and smithing hearths in Prague (Havrda et al. 2001), Brno (Malý, Zapletalová 2007), and other Bohemian and Moravian medieval towns (Pleiner 2006).

The metal bronze and lead droplets from Olomoucká Street in contrast provide evidence of base metal processing as well. This form of production is poorly evidenced in our medieval towns and has only been recorded recently in Brno and the New and Old towns of Prague (Procházka et al. 2011; Podliska, Zavřel 2006). It is congruent, however, with the above-mentioned prehistoric and medieval exploitation of all forms of metal ores in the Uničov area, i.e. in the Jeseníky Mountains.

5. Conclusion

Recent findings of slag and metal droplets in Uničov, dated to the 13th century, provide evidence of both iron smithing and base metal casting in the medieval town. These and other finds from Uničov indicate the importance of the town in terms of ore mining and working in the 1st half of the 13th century. The mining district of Uničov was not accidentally codified as early as 1234 when the rules and tributes of gold mining were determined. Although the original reason for the codification was the acquisition of gold, it was undoubtedly rapidly complemented with silver, lead, and iron mining and processing.

Acknowledgement

Our thanks are due to Václav Vávra and Jindřich Štelcl from the Department of Geology in Brno for providing thin section photos and the SEM-EDX analysis and to Petr Sulovský of the Department of Geology in Olomouc for the XRF analysis. The research was partially funded by the Ministry of Culture supporting the long-term development of the National Heritage Institute.

References

CDB II: Codex diplomaticus et epistolaris regni Bohemiae V-2, (1,198–1,230). G Fridrich (Ed.). Praha 1912.

CDB III/1: Codex diplomaticus et epistolaris regni Bohemiae V-3.1 (1,231–1,238). G. Fridrich (Ed.). Praha 1943.

ALBERGHINA, M. F., BARRACO, R., BRAI, M., SCHILLACI, T., TRANCHINA, L. 2011: Integrated analytical methodologies for the study of corrosion processes in archaeological bronzes, Spectrochimica acta part B: Atomic spectroscopy 66 (2), 129–137.

BLÁHA, J. 1988: Předběžná zpráva o objevu předvelkomoravského ústředí v Olomouci, Archaeologia historica 13, 155–170.

BRADÁK, B., SZAKMÁNY, G., JÓZSA, S., PŘICHYSTAL, A. 2009: Application of magnetic susceptibility on polished stone tools from Western Hungary and the Eastern part of the Czech Republic (Central Europe), Journal of Archaeological Science 36 (10), 2437–2444.

FALTÝNEK, K., KAISER, L., ŠLÉZAR, P., VEČEŘA, P. 2010: Uničov (okr. Olomouc). Masarykovo náměstí, Přehled výzkumů 51, 479–480.

FOJT, B., VODA, O. 2011: Stříbro moravskoslezských Jeseníků, Severní Morava 97/55, 63–64.

FOJT, B., VODA, O. 2012: Zlato moravskoslezských Jeseníků, Severní Morava 98/56, 63–69.

GOŠ, V. 1988: Slovanské osídlení severní Moravy. In: Rodná země. Brno, 181–190.

GOŠ, V., KAREL, J. 2003: Počátky Rýmařova. Nový pohled na předlokační osadu města, Archaeologia historica 28, 297–302.

HAVRDA, J., PODLISKA, J., ZAVŘEL, J. 2001: Surovinové zdroje, výroba a zpracování železa v raně středověké Praze (historie, současný stav a další perspektivy bádání), Archeologické rozhledy 53, 91–118.

HLUBEK, L. 2010: Pravěké a středověké osídlení katastru obce Želechovice (okr. Olomouc), Zprávy Vlastivědného muzea v Olomouci 300, 81–100.

HRUBÝ, P., JAROŠ, Z., KOČÁR, P., MALÝ, K., MIHÁLYIOVÁ, J., MILITKÝ, J., ZIMOLA, D. 2006: Středověká hornická aglomerace na Starých Horách u Jihlavy, Památky archeologické 97, 171–264.

KAREL, J. 2010: Stará Ves a Žďárský Potok v dějinách Moravy. Obecní úřad ve Staré Vsi, Stará Ves.

KAREL, J. 2011: Starobylé doly hankštejnské a kamenohorské, Střední Morava 31, Kulturně historická revue, 4–27.

KLÁPŠTĚ, J. 2005: Proměna českých zemí ve středověku. Academia, Praha.

KOUŘIL, P. 2006: Život v raně středověkém městě ve světle archeologie. Opava – Praha, 27–42.

KOUŘIL, P., PRIX, D., WIHODA, M. 2000: Hrady českého Slezska. AÚ AV ČR Brno, Brno – Opava.

LUDIKOVSKÝ, K. 1960: Staroslovanské železářské pece v Žerotíně, Přehled výzkumů 1959, 106–107.

LUTOVSKÝ, M. 2001: Encyklopedie slovanské archeologie v Čechách, na Moravě a ve Slezsku. Libri, Praha.

MALÝ, K., ZAPLETALOVÁ, D. 2007: Železářská kovovýroba v pravobřežní části Starého Brna, Archeologia technica 18, 18–31.

MERTA, D., PEŠKA, M. 2002: Železářský výrobní areál z počátku 13. století v prostoru náměstí Svobody v Brně, Archeologia technica 13, 33–42.

MĚŘÍNSKÝ, Z. 2002: České země od příchodu Slovanů po Velkou Moravu I. Libri, Praha.

MICHNA, P. 1980: Dvě sídlištní stavby z počátků lokačního Uničova. Příspěvek k otázce zemnic ve městech a vesnicích 13. století, Vlastivědný věstník moravský 32, 161–186.

NOVÁK, J. 1990: Doklady hornictví neželezných kovů na severní Moravě. Výsledky báňskohistorického výzkumu z let 1973–1987, Sborník památkové péče v Severomoravském kraji 8, 25–44.

NOVOTNÝ, P., ZIMÁK, J. 2003: Zlaté Hory. Historie a současnost ložiska zlata evropského významu. Memoria, Olomouc – Zlaté Hory.

PLAŠTIAKOVÁ, M. 2009: Uničov – ul. Nemocniční, bytové domy. MS. Excavation report. Deposited: Archaia Olomouc.

PLEINER, R. 1955: Výroba železa ve slovanské huti u Želechovic na Uničovsku. Rozpravy Československé akademie věd 65/6, řada SV. Nakladatelství ČSAV, Praha.

PLEINER, R. 1958: Základy slovanského železářského hutnictví v českých zemích. Vývoj přímé výroby železa z rud od doby halštatské do 12. věku. Academia, Praha.

PLEINER, R. 2000: Iron in Archaeology: The European bloomery smelters. AÚ AV ČR, Praha.

PLEINER, R. 2006: Iron in archeology: Early European blacksmiths. AÚ AV ČR, Praha.

PODLISKA, J., ZAVŘEL, J. 2006: K problematice identifikace a interpretace archeometalurgického materiálu na příkladu raně středověké Prahy, Archaeologia historica 31, Brno, 387–402.

PROCHÁZKA, R., HLOŽEK, M., HOLUBOVÁ-ZÁVODNÁ, B. 2011: Doklady neželezné metalurgie ze sklonku 12. století z Brna, Josefské ulice, Archeologické rozhledy 63, 65–89.

RAMBOUSEK, P., ŘEPKA, V. (Eds.) 2009: Hornická činnost a její následky v hornobenešovském a hornoměstském revíru. Česká geologická služba, Praha.

SCHIRMEISEN, K. 1943: 15 Jahre Vorgeschichtsforschung in Mähr.-Neustädter gebiet. Verlag des Mährischen Landesmuseums, Brünn.

SPURNÝ, F. 1972: Severomoravské železářství do Bílé hory. Vlastivědný ústav, Šumperk.

ŠESTÁKOVÁ, K. 2012: Doklady protohistorické, středověké a novověké těžby nerostných surovin na Uničovsku. MS. Bachelor thesis. Deposited: Chair of history, Palacký University in Olomouc, Olomouc.

ŠLÉZAR, P., in press: Uničov (okr. Olomouc). Olomoucká ul., Přehled výzkumů 53.

VEČEŘA, J. 2002: Historie dolování ve zlatohorském rudním revíru. Jesenicko, Vlastivědný sborník 3, 18–31.

WIHODA, M. 2009: „Civibus nostris libertatem damus“. Dlouhé počátky městského zřízení na Moravě. In: Středověká města na Moravě a v sousedních zemích. Hodonín, 161–175.

ZMEŠKALOVÁ, B., DOLNÍČEK, Z., KOLBINGER, D. 2010: Nálezy artefaktů po železářské výrobě v Rajnochovicích a Komárně (Hostýnské vrchy), Archeologia technica 21, 31–42.

*Corresponding author. E-mail: martin.monik@gmail.com

Figure 1. Location of Uničov in the Czech Republic.

Figure 2. Masaryk Square and Olomoucká Street in Uničov – locations with evidence of 13th century metalworking. Stable cadastre map from 1834.

Figure 3. Piece of slag – sample no. 1.

Figure 4. Piece of slag – sample no. 2.

Figure 5. Piece of slag – sample no. 3.

Figure 6. Microphotography of sample no. 1 with fayalite laths and wüstite dendrites, XPL (photo by V. Vávra).

Figure 7. Microphotography of sample no. 2 with wüstite dendrites and secondary limonite, PPL (photo by V. Vávra).

Figure 8. Microphotography of organic remains in the slag conserved in limonite, SEM (photo by J. Štelcl).

Figure 9. Microphotography of sample no. 1 with a pure iron fragment (bright) among the fayalite and wüstite phases, SEM (photo by J. Štelcl).

Figure 10. Lead droplet from Olomoucká Street.

0 3 cm

0 3 cm

0 3 cm

Table 1. Material composition of mineral phases in slag sample no. 1 (in wt%, normalized to 100%), SEM-EDX analysis.

|

|

Measured spectrum (in wt%, normalized to 100%) |

||||||||

|

Oxide type |

Spectrum 1 wüstite |

Spectrum 2 fayalite |

Spectrum 3 glass |

Spectrum 4 fayalite |

Spectrum 5 limonite |

Spectrum 6 fayalite |

Spectrum 7 wüstite |

Spectrum 8 glass |

Spectrum 9 wüstite |

|

Al2O3 |

1.46 |

16.58 |

11.13 |

3.28 |

1.41 |

15.6 |

|

||

|

TiO2 |

0.56 |

0.49 |

|

||||||

|

FeO |

97.98 |

59.88 |

22.29 |

57.49 |

78.22 |

59.51 |

98.59 |

24.04 |

100 |

|

MgO |

2.78 |

2.4 |

|

||||||

|

SiO2 |

33.38 |

38.26 |

23.44 |

13.15 |

34.19 |

37.89 |

|

||

|

CaO |

2.24 |

14.1 |

1.59 |

2.23 |

13.3 |

|

|||

|

MnO |

1.73 |

1.67 |

0.7 |

|

|||||

|

Na2O |

0.92 |

0.55 |

|

||||||

|

P2O5 |

3.05 |

3.75 |

2.78 |

|

|||||

|

K2O |

4.8 |

7.44 |

5.15 |

|

|||||

|

Ion amount for 8 oxygen atoms |

|||||||||

|

Al2O3 |

0.16 |

1.04 |

0.87 |

0.29 |

0.16 |

0.99 |

|

||

|

TiO2 |

0.04 |

0.02 |

|

||||||

|

FeO |

7.68 |

3.21 |

0.99 |

3.2 |

4.88 |

3.17 |

7.77 |

1.09 |

8 |

|

MgO |

0.27 |

0.23 |

|

||||||

|

SiO2 |

2.14 |

2.04 |

1.56 |

0.98 |

2.18 |

2.05 |

|

||

|

CaO |

0.15 |

0.81 |

0.13 |

0.15 |

0.77 |

|

|||

|

MnO |

0.09 |

0.09 |

0.03 |

|

|||||

|

Na2O |

0.1 |

0.06 |

|

||||||

|

P2O5 |

0.14 |

0.24 |

0.13 |

|

|||||

|

K2O |

|

|

0.33 |

0.63 |

|

|

|

0.36 |

|

0 5 cm